100% Original Factory Steel Products - OEM custom electric gold plating chrome parts Service – LAMBERT

100% Original Factory Steel Products - OEM custom electric gold plating chrome parts Service – LAMBERT Detail:

Short Description

Is using the principle of electrolytic plating on some metal surface on a thin layer of other metal or alloy plating process, is the use of electrolytic action made of metal or other materials adhered on the surface of the parts of a layer of metal film technique to prevent metal oxidation (rust), improve the wear resistance and electric conductivity, reflective, corrosion resistance and improve aesthetics, and so on.

Product Description

Coating is mostly a single metal or alloy, such as titanium palladium, zinc, cadmium, gold or brass, bronze, etc. There are also dispersion layer, such as nickel – silicon carbide, nickel – fluoride fossil ink; There are cladding layers, such as copper – nickel – chromium layer on steel, silver – indium layer on steel and so on. In addition to iron based cast iron, steel and stainless steel, there are also non-iron metals, or ABS plastics, polypropylene, polysulfone and phenolic plastics, but the plastics must undergo special activation and sensitization treatment before electroplating.

The electroplating process is basically as follows:

Plated metal at anode

The material to be plated is at the cathode

The anode and cathode are connected by an electrolyte solution of positive ions of the plated metal

When a direct current is applied, the metal at the anode oxidizes (loses electrons) and the positive ions in the solution are reduced (gains electrons) at the cathode to form atoms and accumulate on the cathode surface.

The beauty of electroplated objects after electroplating is related to the size of the current, the smaller the current, the more beautiful the electroplated objects will be; Otherwise, there will be some uneven shapes.

The main uses of electroplating include protection against metal oxidation (e.g. corrosion) and decoration. Many coins are also electroplated.

Effluent from electroplating, such as defunct electrolytes, is a significant source of water pollution. Electroplating process has been widely used in semiconductor and microelectronics components lead frame process.

VCP: vertical continuous electroplating, new machine for PCB, better quality than traditional suspension electroplating

Aluminum plating solution formula process flow:

High temperature weak alkali etching → cleaning → pickling → cleaning → zinc immersion → cleaning → secondary zinc immersion → cleaning → pre-copper plating → cleaning → pre-silver plating → cyanide bright silver plating → recovery washing → cleaning → silver protection → cleaning → drying.

From the process, the selected protective material must be resistant to high temperature (about 80℃), alkali resistance, acid resistance, secondly, the protective material can be easy to peel off after silver plating.

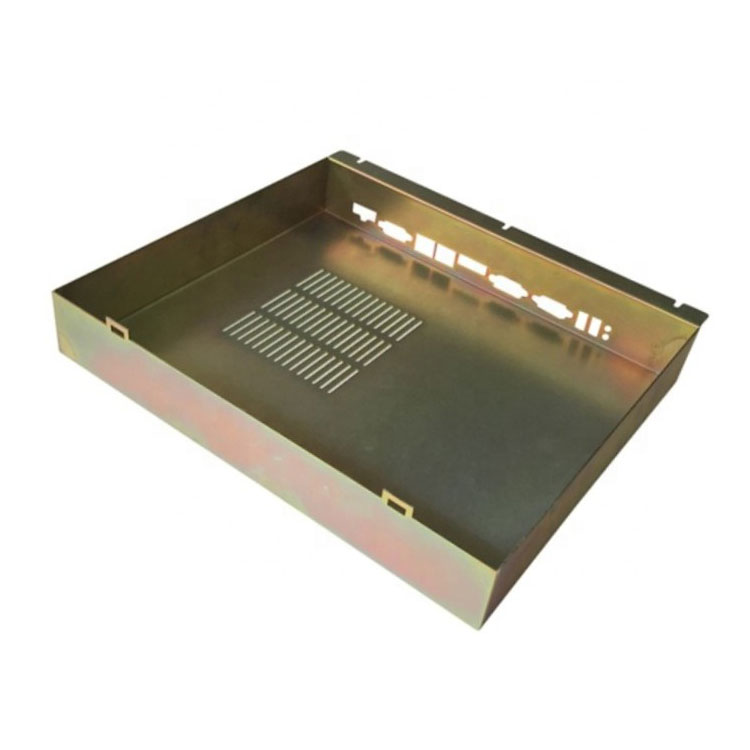

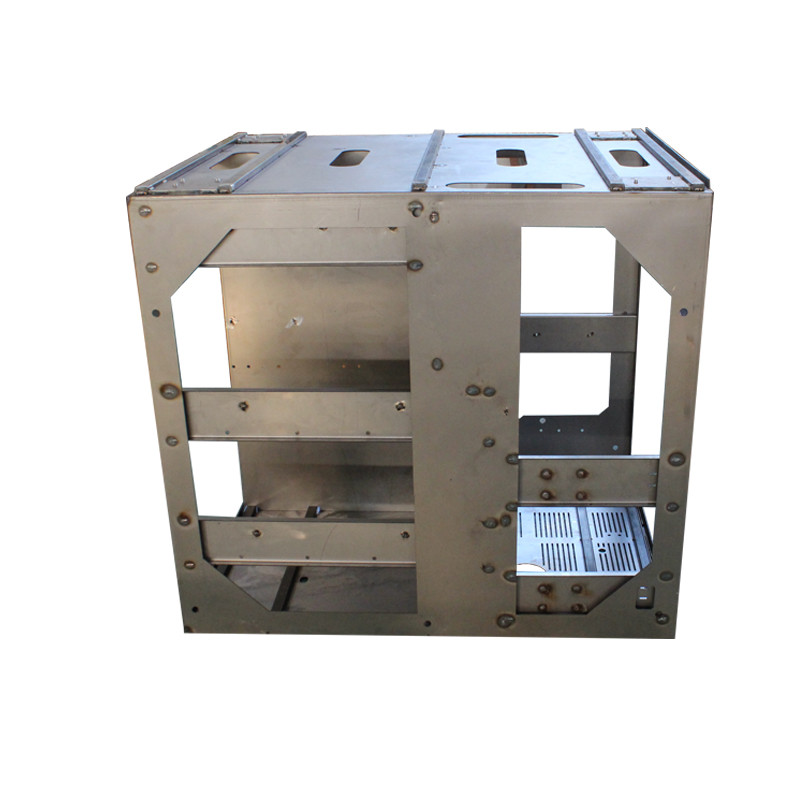

Product detail pictures:

Related Product Guide:

We strive for excellence, service the customers", hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for 100% Original Factory Steel Products - OEM custom electric gold plating chrome parts Service – LAMBERT , The product will supply to all over the world, such as: Belize, Congo, Oslo, Actually need to any of those objects be of interest to you, make sure you allow us to know. We'll be delighted to present you a quotation on receipt of one's comprehensive specs. We've our individual specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

Lambert sheet metal custom processing solutions provider.

With ten years of experience in foreign trade, we specialise in high precision sheet metal processing parts, laser cutting, sheet metal bending, metal brackets, sheet metal chassis shells, chassis power supply housings, etc. We are proficient in various surface treatments, brushing, polishing, sandblasting, spraying, plating, which can be applied to commercial designs, ports, bridges, infrastructure, buildings, hotels, various piping systems, etc. We have advanced processing equipment and a professional technical team of over 60 people to provide high quality and efficient processing services to our customers. We are able to produce sheet metal components of various shapes to meet our customers’ complete machining needs. We are constantly innovating and optimising our processes to ensure quality and delivery, and we are always “customer focused” to provide our customers with quality service and help them achieve success. We look forward to building long-term relationships with our customers in all areas!

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.