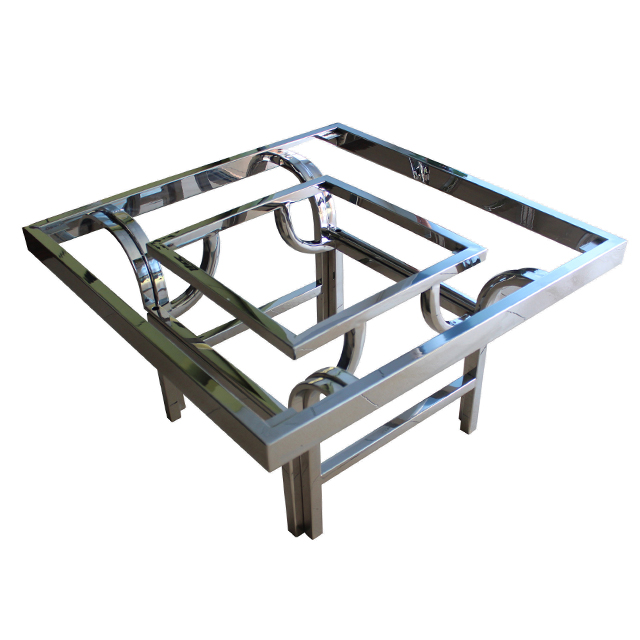

100% Original Stamping Sheet Metal - Wholesale custom stainless steel sheet metal table legs frames – LAMBERT

100% Original Stamping Sheet Metal - Wholesale custom stainless steel sheet metal table legs frames – LAMBERT Detail:

Our Advantages

Competitive prices.

10 years of professional custom processing experience.

100% foreign trade factory, rich export experience.

Customized and designed according to the requirements of customers. Size, material, shape, surface treatment, logo, packaging, etc. can be customized.

We have laser cutting machine, numerical control bending machine, 3D bending machine, welding robot and other advanced processing equipment to meet various processing accuracy requirements.

Strict quality control, 100% QC inspection before delivery.

| Keywords: | stainless steel table legs, furniture frames. |

| Thickness: | 0.2-30mm, According To Customer Request. |

| Shape and Size: | Custom. According To Customer’s Drawing Or Request |

| Machining: | Laser Cutting, Bending,welding, etc. |

| Standard: | Custom High Precision, Non-Standard |

| Materials: | Stainless steel plate, SUS pipes. |

| Tolerance: | Laser Cutting: ±0.05mm, Bending:±0.05,Stamping: ±0.02mm, Welding: ± 0.2mm |

| Drawing Accepted: | All Formats(UG,ProE, Auto Cad, Solidworks, And So On) |

| Finishing | Drawing, Brushing, polishing, Chrome, Powder Coating etc. |

| Service Mode: | OEM or ODM |

Product detail pictures:

Related Product Guide:

"Control the quality by the details, show the power by quality". Our enterprise has strived to establish a remarkably efficient and stable team team and explored an effective excellent control system for 100% Original Stamping Sheet Metal - Wholesale custom stainless steel sheet metal table legs frames – LAMBERT , The product will supply to all over the world, such as: Thailand, Philippines, Paraguay, Our company sticks to the principle of "high quality, reasonable price and timely delivery". We sincerely hope to establish good cooperative relationships with our new and old business partners from all parts of the world. We hope to work with you and serve you with our excellent goods and services. Welcome to join us!

Lambert sheet metal custom processing solutions provider.

With ten years of experience in foreign trade, we specialise in high precision sheet metal processing parts, laser cutting, sheet metal bending, metal brackets, sheet metal chassis shells, chassis power supply housings, etc. We are proficient in various surface treatments, brushing, polishing, sandblasting, spraying, plating, which can be applied to commercial designs, ports, bridges, infrastructure, buildings, hotels, various piping systems, etc. We have advanced processing equipment and a professional technical team of over 60 people to provide high quality and efficient processing services to our customers. We are able to produce sheet metal components of various shapes to meet our customers’ complete machining needs. We are constantly innovating and optimising our processes to ensure quality and delivery, and we are always “customer focused” to provide our customers with quality service and help them achieve success. We look forward to building long-term relationships with our customers in all areas!

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.