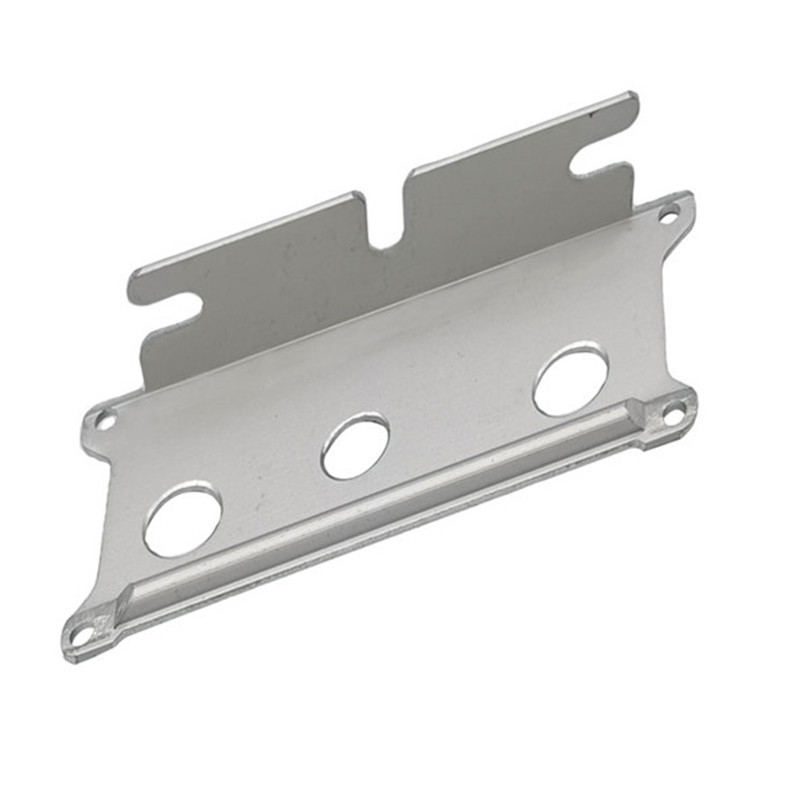

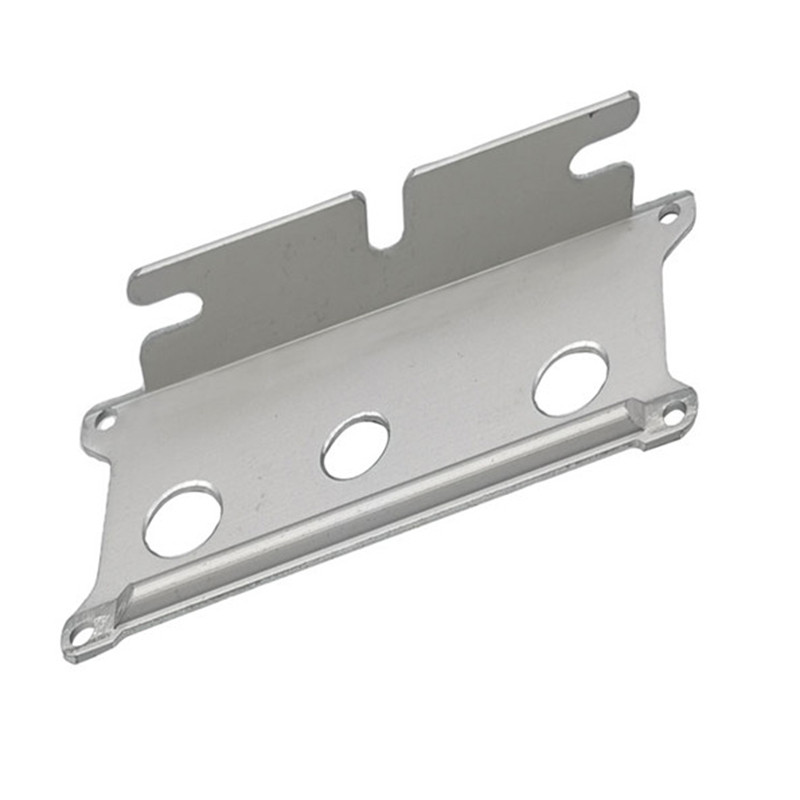

2022 Good Quality Stainless Steel Tube Bending - custom alloy aluminum steel sheet metal bending Service – LAMBERT

2022 Good Quality Stainless Steel Tube Bending - custom alloy aluminum steel sheet metal bending Service – LAMBERT Detail:

Short Description

Sheet metal bending is an operation that involves the use of force to change the shape of a sheet. This is done to obtain the shape or shape needed for the manufacturing process. The external force applied only changes the external characteristics of the sheet. However, sheet metal parameters for one type, such as length and thickness, remain unchanged. The ductility of the metal plate further enables it to be used in a variety of molding processes.

Sheet metal methods include V bend, roll bend, U bend, wipe bend, rotary bend.

Product Description

V bend

This is the most common method of sheet bending, as it is used for most bending projects. It uses a tool called a punch and a V-die to bend the plate at the desired Angle. In this process, the bending punch is stamped on a metal plate placed above the V-shaped die.

The sheet metal forming Angle depends on the punch pressure point. This makes the method simple and effective, as it can be used to bend steel plates without changing their position.

Roll bending

Roll bending is a method used to bend a sheet of metal into a roll or curved shape. The process uses a hydraulic press, a bending machine and three sets of rollers to create different bends or large bends. It can be used to form conical, tubular and hollow shapes because it uses the distance between rollers to create bends and curves.

U bend

A U-bend is similar to a V-bend. It uses the same instrument (except for u-shaped molds) and process, but the only difference is that the shape formed is U-shaped. U-bend is very popular. However, other methods have the flexibility to generate shapes.

Wipe bend

Wipe bending is another method used to bend metal edge plates. The process depends on wiping the mold. For example, the metal plate must be pushed correctly onto the wipe mold. The wiper is also responsible for determining the inner bending radius of the sheet metal.

Rotary bend

This bending method has an advantage over wipe bending or V-bending because it does not cause scratching of the material surface. It is also ideal because it can bend the material into sharp angles. For example, it is used to bend angles greater than 90.

Product detail pictures:

Related Product Guide:

Our commission should be to provide our customers and consumers with ideal top quality and aggressive portable digital products for 2022 Good Quality Stainless Steel Tube Bending - custom alloy aluminum steel sheet metal bending Service – LAMBERT , The product will supply to all over the world, such as: Bahrain, Rio de Janeiro, Singapore, we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work wholeheartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

Lambert sheet metal custom processing solutions provider.

With ten years of experience in foreign trade, we specialise in high precision sheet metal processing parts, laser cutting, sheet metal bending, metal brackets, sheet metal chassis shells, chassis power supply housings, etc. We are proficient in various surface treatments, brushing, polishing, sandblasting, spraying, plating, which can be applied to commercial designs, ports, bridges, infrastructure, buildings, hotels, various piping systems, etc. We have advanced processing equipment and a professional technical team of over 60 people to provide high quality and efficient processing services to our customers. We are able to produce sheet metal components of various shapes to meet our customers’ complete machining needs. We are constantly innovating and optimising our processes to ensure quality and delivery, and we are always “customer focused” to provide our customers with quality service and help them achieve success. We look forward to building long-term relationships with our customers in all areas!

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.