8 Year Exporter Fabrication Metal - Customized high quality waterproof stainless steel electric box – LAMBERT

8 Year Exporter Fabrication Metal - Customized high quality waterproof stainless steel electric box – LAMBERT Detail:

Our Advantages

About this project

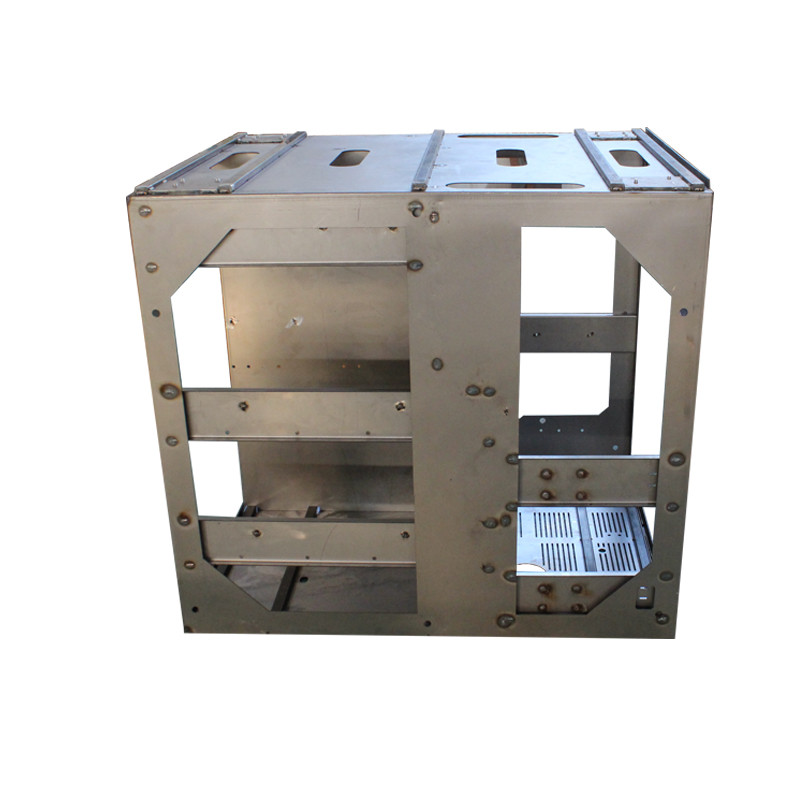

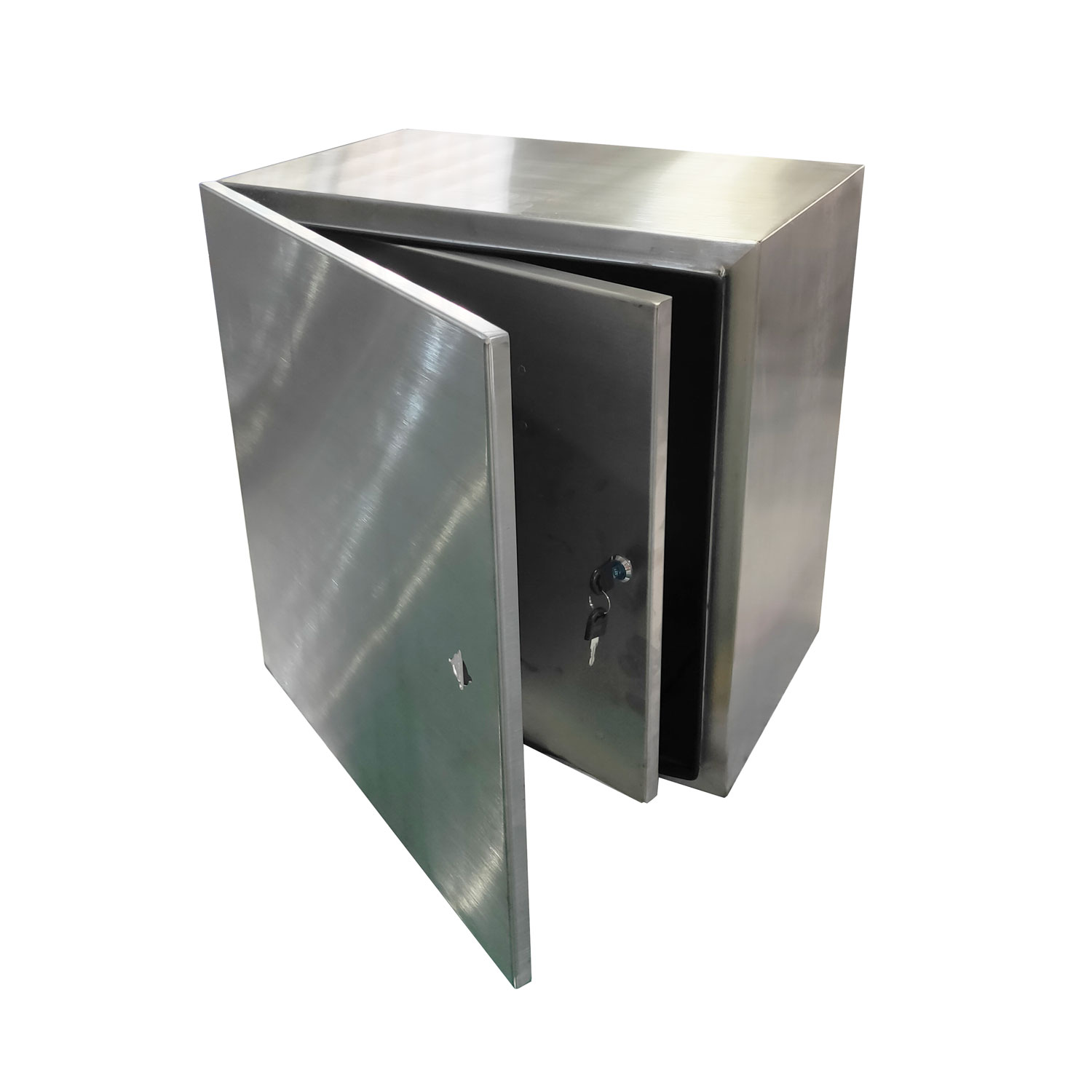

Solid structure: the electrical shell is made of high-quality stainless steel plate, which has been accurately cut, bent and welded. It has strong weather resistance and can prevent rain erosion.

Waterproof sealing strip: the electrical box is sealed with rubber strips to prevent rainwater from entering and protect the internal electrical equipment. Different waterproof and dustproof grades can be customized according to your requirements.

Reinforced lock and hinge: the electrical shell box adopts high-quality lock cylinder, and the structure is precise and firm, which is not easy to fall off

Wdely used: the electric box is suitable for indoor and outdoor applications, protecting circuits and preventing corrosion. It is suitable for various applications from industrial equipment to medical equipment, such as factories, shopping malls, squares, construction sites, residences, courtyards, etc.

Product detail pictures:

Related Product Guide:

We always continually offer you the most conscientious purchaser services, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for 8 Year Exporter Fabrication Metal - Customized high quality waterproof stainless steel electric box – LAMBERT , The product will supply to all over the world, such as: India, El Salvador, Estonia, Our company regards "reasonable prices, high quality,efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits in future. Welcome to contact us.

Lambert sheet metal custom processing solutions provider.

With ten years of experience in foreign trade, we specialise in high precision sheet metal processing parts, laser cutting, sheet metal bending, metal brackets, sheet metal chassis shells, chassis power supply housings, etc. We are proficient in various surface treatments, brushing, polishing, sandblasting, spraying, plating, which can be applied to commercial designs, ports, bridges, infrastructure, buildings, hotels, various piping systems, etc. We have advanced processing equipment and a professional technical team of over 60 people to provide high quality and efficient processing services to our customers. We are able to produce sheet metal components of various shapes to meet our customers’ complete machining needs. We are constantly innovating and optimising our processes to ensure quality and delivery, and we are always “customer focused” to provide our customers with quality service and help them achieve success. We look forward to building long-term relationships with our customers in all areas!

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.