ZHONGSHAN LAMBERT PRECISION HARDWARE CO., LTD.

Was established in 2012. We are an export production base specializing in customized sheet metal processing and NC processing.

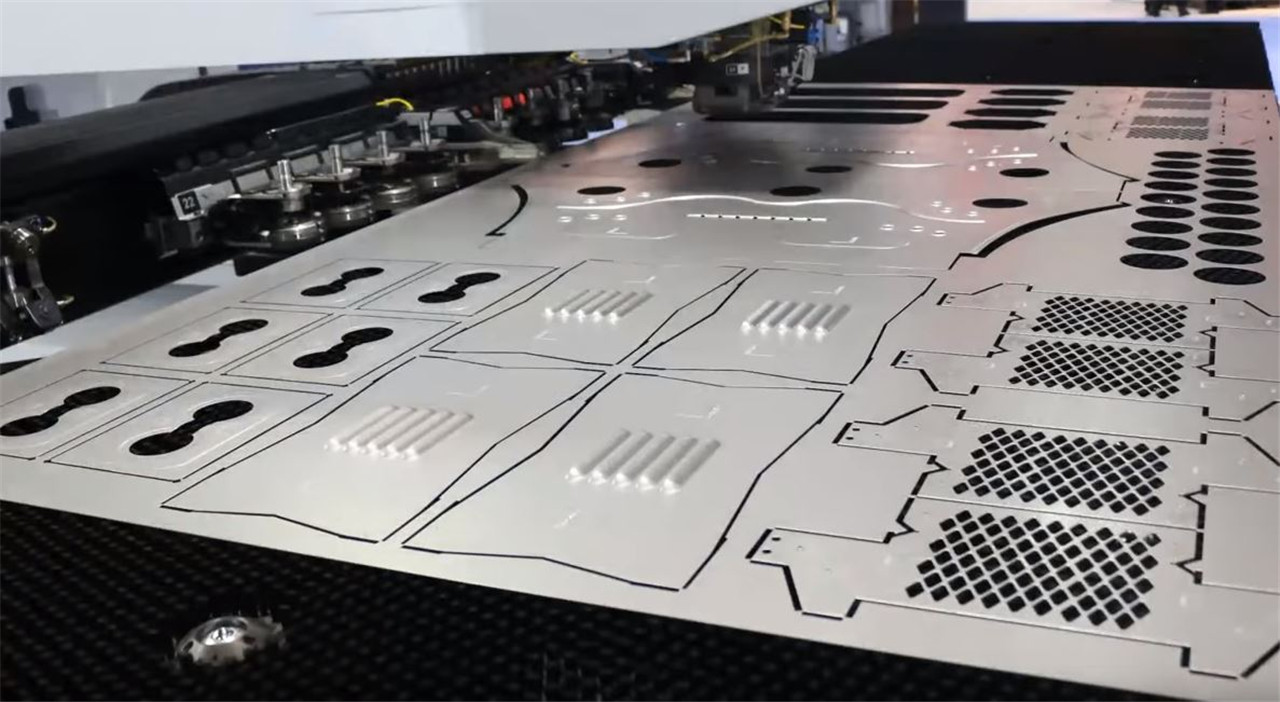

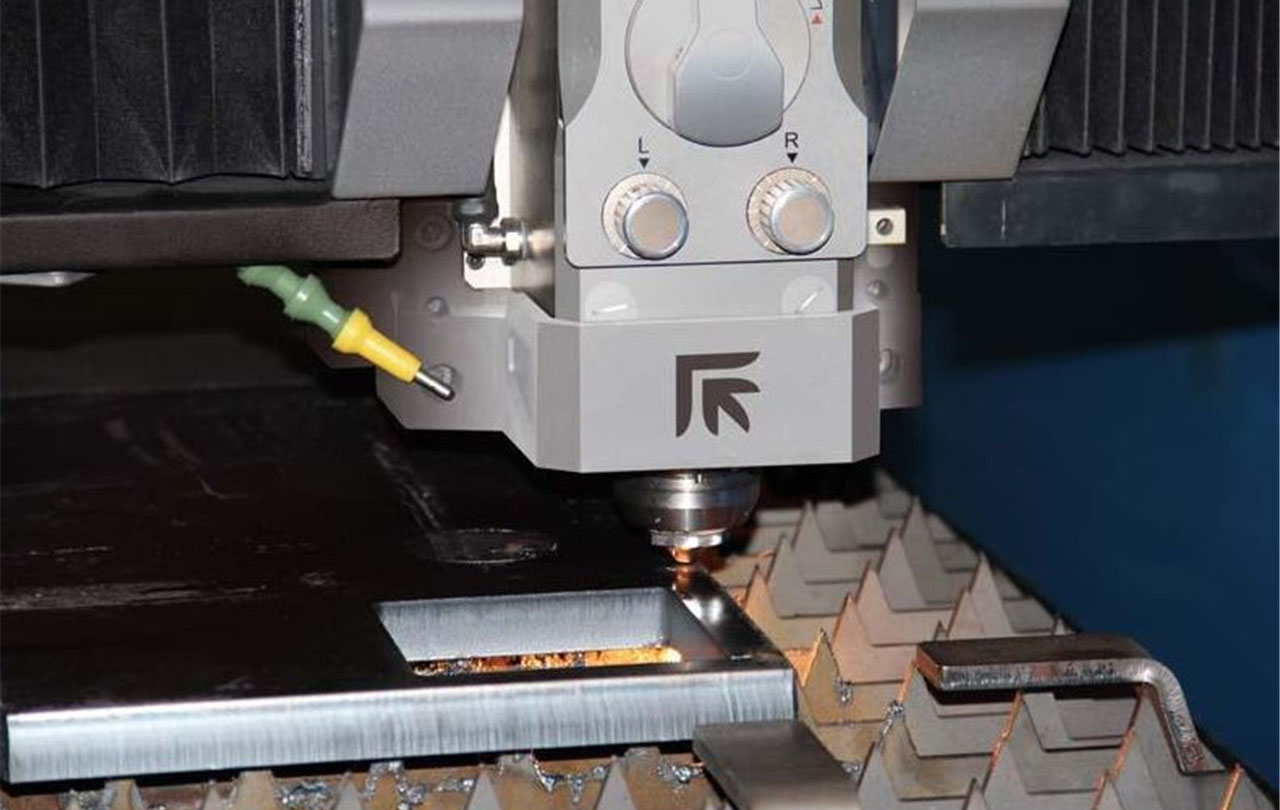

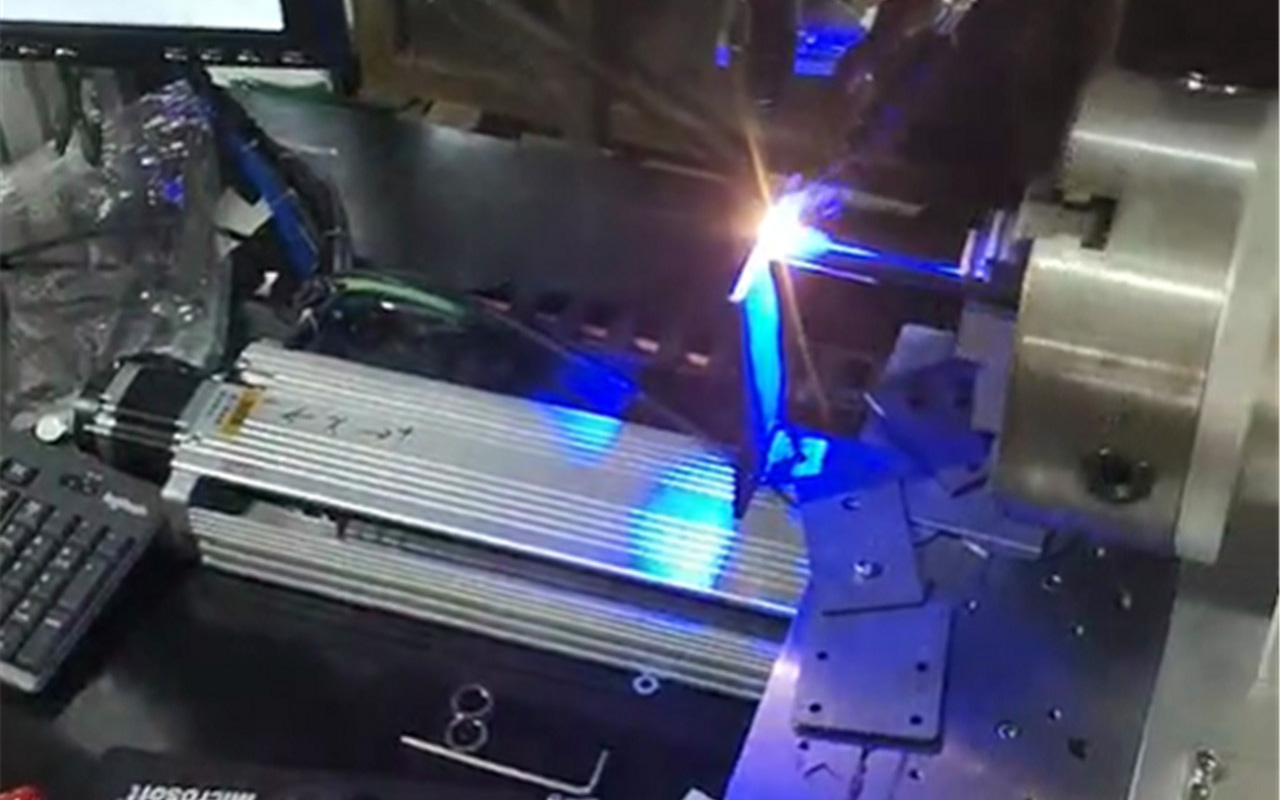

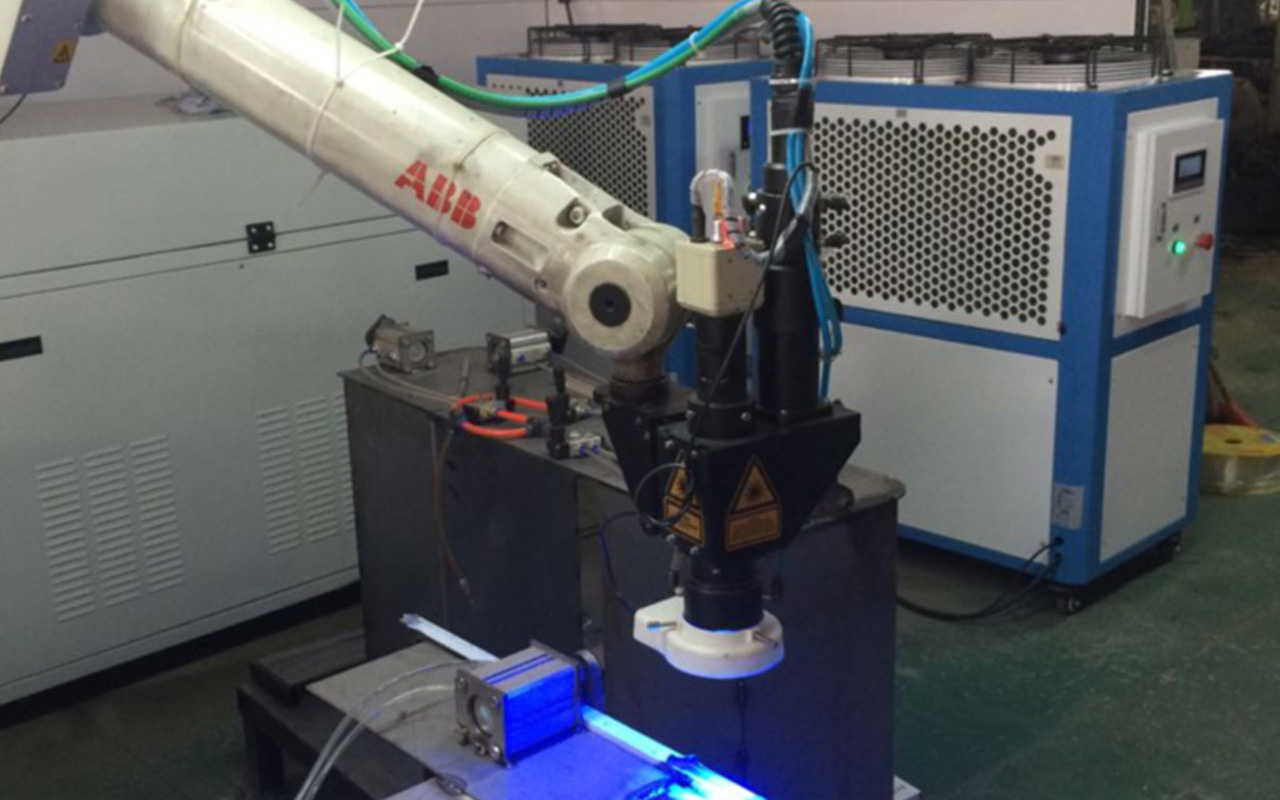

We have advanced equipment. We have German trump laser cutting machine, CNC punching, CNC bending, laser welding, slotting and other equipment. Our processing accuracy is within 0.02-0.20 mm.

We have an experienced team. We always adhere to the improvement of production technology and are committed to providing high-quality products and efficient services. We have more than 10 engineers, more than 30 technical masters and more than 100 skilled production workers.

While we strive to improve production accuracy and provide product qualification rate, we also pursue industrial automation to reduce costs.

Our services include: customized finished products, 3D printing, various metal products, machine parts, processing of various materials (plates, pipes and profiles, etc.), various surface treatments, etc.

For example: laser cutting parts, machining parts, stamping parts, control box, instrument box, insulation box, OEM metal box, steel support, steel hotel table, etc.

ADVANTAGE

• The high-performance and flexible standard press TruPunch 2000 has a wide range of workpieces that can be machined.

• The X/Y axis linkage speed can reach 108m/min, and the rush speed is up to 900 times per minute.

•Even at lower load operation, it also maintains good production .

• Ensure the quality of the corner cut.

• Real-time monitoring of the distance between the nozzle and the plate.

• Stable machining of precision small holes that are much smaller than the plate thickness for precise cutting.

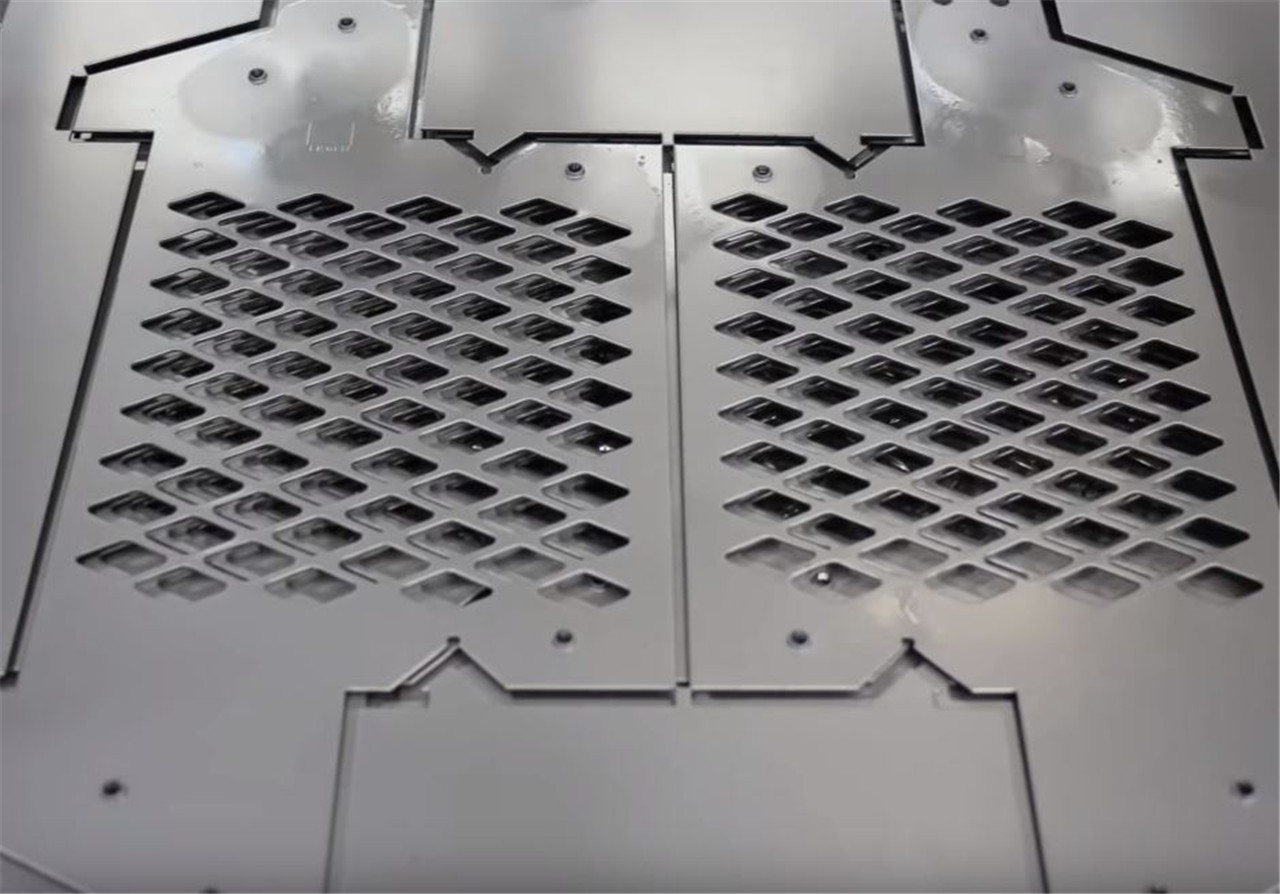

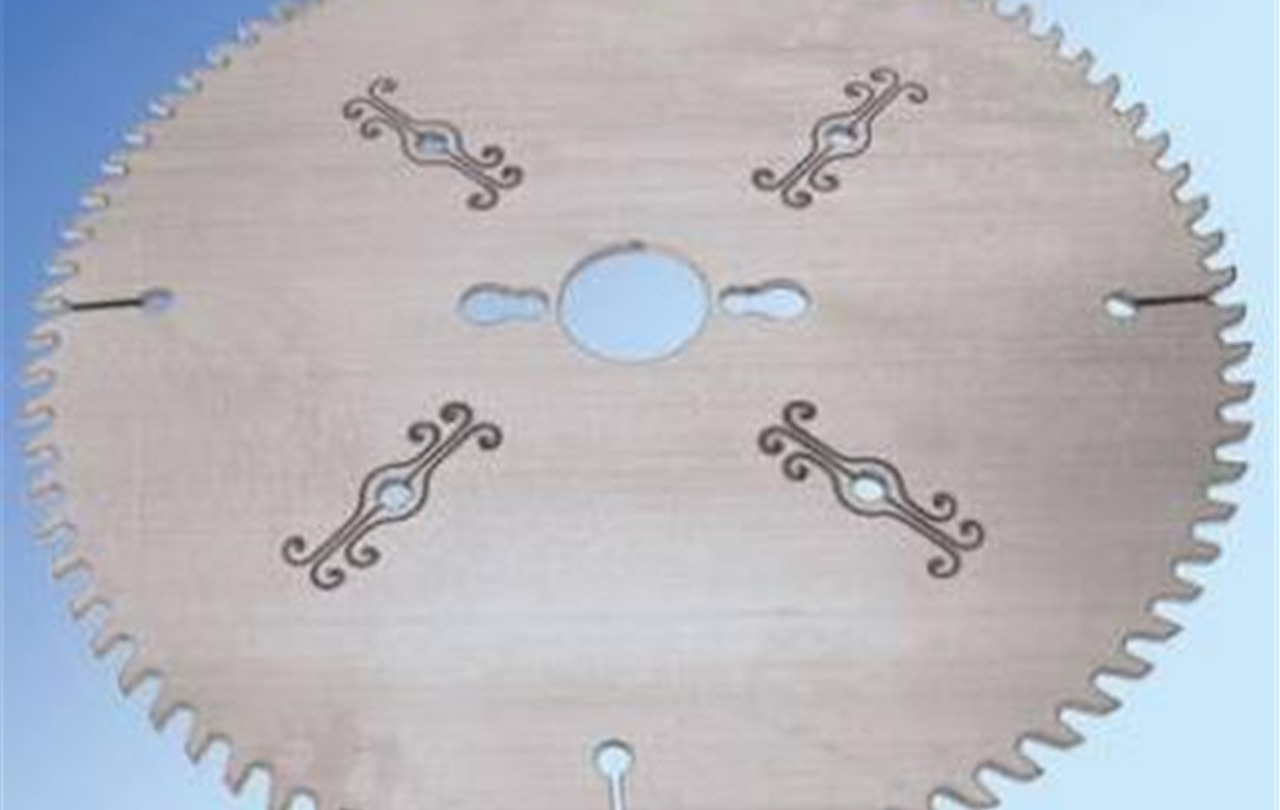

• Can be cut in almost any shape.

• Small heat affected zone, high cutting precision, and the automatic typesetting nesting material can save materials.

CNC BENDER

LASER PIPE CUTTER

• Change the band saw and drill bit for milling or chamfering.

• Reduce production time and reduce manufacturing costs.

• High flexibility, high precision and high quality.

• Process open profiles and flat steels, as well as profiles of various shapes.

• Automatic nesting of elements reduces waste and optimizes manufacturing time.

• Automatic parameter setting and feed speed.