Cheap PriceList for Fabrication Welding - Custom High quality electric box Distribution Box – LAMBERT

Cheap PriceList for Fabrication Welding - Custom High quality electric box Distribution Box – LAMBERT Detail:

Detail Information

| Keywords: | electric box, electric distribution box, metal electrical box, electrical enclosure box | Materials: | Stainless steel, Aluminum,and So On |

| Thickness: | 0.2-1mm | Tolerance: | Bending: ±0.1mm, Press Stamping: ±0.02mm |

| Shape: | According To Customer’s Drawing Or Request | Size: | Customized Size |

| Application: | Indoor, Outdoor, Industry, Agriculture, Machinery, Chemical, Pharmaceutical And So On | Drawing Accepted: | All Formats(UG,ProE, Auto Cad, Solidworks, And So On) |

| Machining: | Stamping,Bending,welding,Polishing,chrome,Etc. | Finish: | Chrome, Powder Coating, Black And Other Color Drawing |

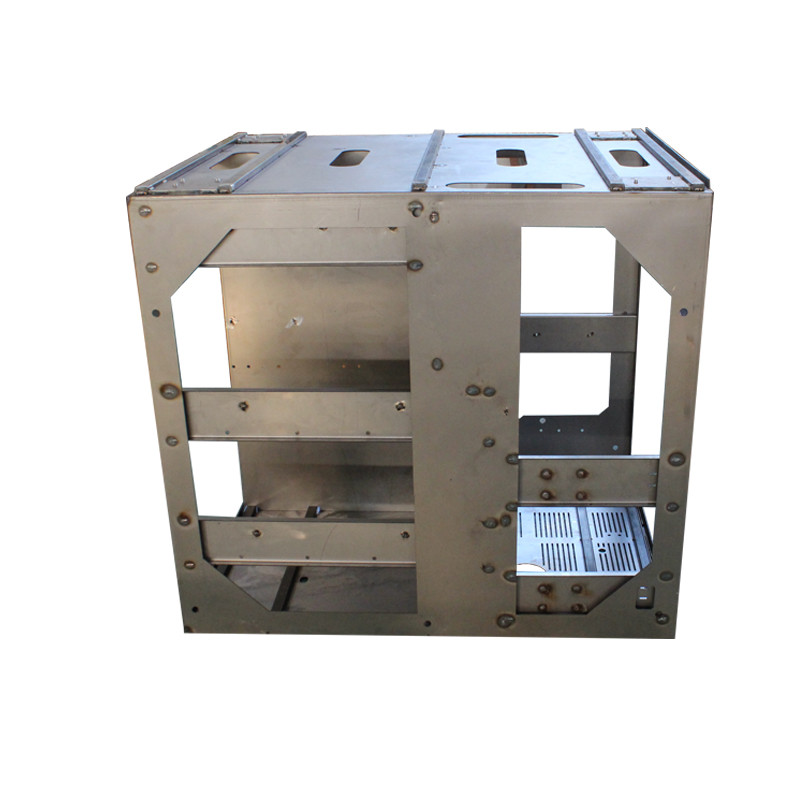

| Type: | sheet metal stainless steel large electric box | Service Mode: | OEM custom sheet metal electric box service |

| Standard: | Custom High Precision Non-Standard | Surface treatment: | Powder coating,chrome,polish,hot dip zinc,etc. |

Short Description

• heavy duty type, welded steel structure.

• with hinge, 180 degree opening and closing cover.

• there are four wall mounting holes on the back.

• durable powder coated surface treatment.

• size: customized according to customer needs. Reference dimensions, 10 inches wide, 10 inches high and 6 inches deep.

Product Description

We provide a series of distribution boxes and junction boxes made of sheet metal for the electronics and power industries. We have distribution boxes with various waterproof and dustproof grades, and the highest protection grade can reach IP67. Our electric box is waterproof, dustproof, environmentally friendly and solid. It is suitable for various occasions from industrial equipment to medical equipment, indoor to outdoor, household to explosion-proof applications.

This kind of junction box with steel structure is very suitable for various electrical applications of junction boxes and junction boxes. The welded steel structure adopts threaded flat cover with keyhole for easy assembly. According to the industry standard conduit size, the box with knock-out holes has concentric knock-out holes that are easy to disassemble on all sides.

These boxes have a hinged cover that can be opened and closed by 180 degrees. It is convenient to install and maintain the electrical components inside.

It is made of all stainless steel or cold rolled plate with powder coating, which has good durability, safety and reliability. Reduce maintenance costs.

Product detail pictures:

Related Product Guide:

With sophisticated technologies and facilities, strict top quality handle, reasonable value, exceptional support and close co-operation with clients, we are devoted to furnishing the ideal worth for our clients for Cheap PriceList for Fabrication Welding - Custom High quality electric box Distribution Box – LAMBERT , The product will supply to all over the world, such as: San Diego, New York, Iraq, Our solutions have national accreditation requirements for qualified, good quality items, affordable value, was welcomed by individuals all over the world. Our goods will continue to improve inside the order and appear forward to cooperation with you, Really should any of those items be of interest to you, please letus know. We will be satisfied to provide you a quotation up on receipt of the detailed needs.

Lambert sheet metal custom processing solutions provider.

With ten years of experience in foreign trade, we specialise in high precision sheet metal processing parts, laser cutting, sheet metal bending, metal brackets, sheet metal chassis shells, chassis power supply housings, etc. We are proficient in various surface treatments, brushing, polishing, sandblasting, spraying, plating, which can be applied to commercial designs, ports, bridges, infrastructure, buildings, hotels, various piping systems, etc. We have advanced processing equipment and a professional technical team of over 60 people to provide high quality and efficient processing services to our customers. We are able to produce sheet metal components of various shapes to meet our customers’ complete machining needs. We are constantly innovating and optimising our processes to ensure quality and delivery, and we are always “customer focused” to provide our customers with quality service and help them achieve success. We look forward to building long-term relationships with our customers in all areas!

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.