China Manufacturer for Dining Table Frame - Customized Sheet Metal Enclosure Powder Coating Service – LAMBERT

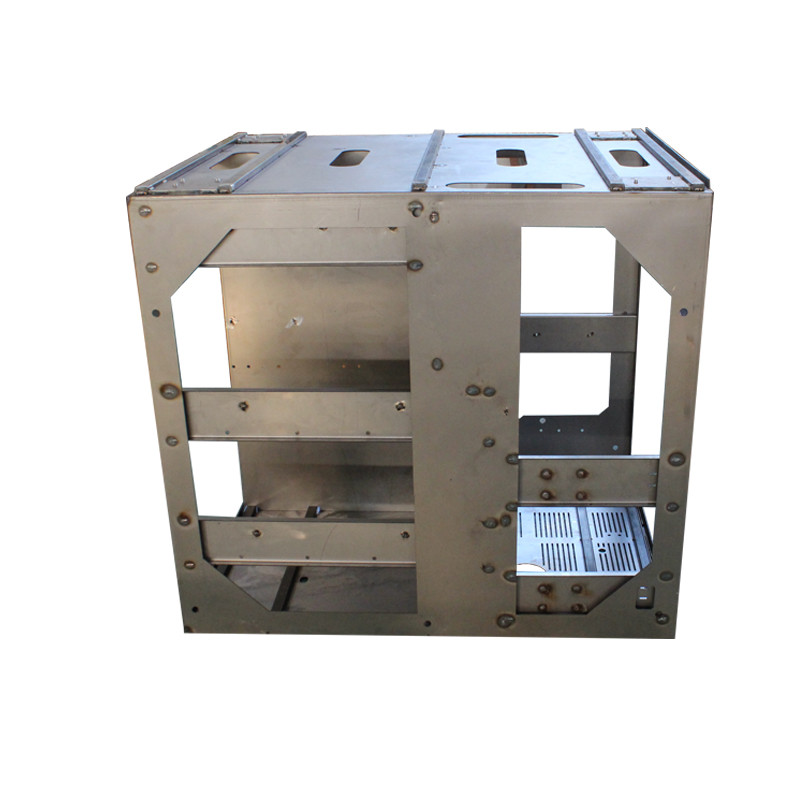

China Manufacturer for Dining Table Frame - Customized Sheet Metal Enclosure Powder Coating Service – LAMBERT Detail:

Short Description

Powder spraying process, also known as powder coating, is a new coating process developed rapidly in recent decades. The raw material used is plastic powder. Coating can get thicker coating, such as coating 100~300μm coating, with general general solvent coating, about 4~6 times, and with powder coating is once can achieve the thickness. The coating has good corrosion resistance. The powder coating does not contain solvent, and has no pollution of three wastes. Using powder electrostatic spraying and other new processes, high efficiency, suitable for automatic line coating; High powder utilization rate, recyclable.a

Product Description

The purpose of dusting

The first is the protection, in order to prolong the life of the workpiece, followed by decorative, beautiful and pleasant. Again, for special purposes, to achieve special performance. Such as: sound insulation, heat insulation, fire prevention and so on.

According to the purpose of painting and different requirements, the coating of painting has several layers, including primer, putty, finish paint, etc.

Bottom paint: it is the lowest layer of coating that is in direct contact with the body of the coated workpiece. The role of the primer layer is to strengthen the adhesion between the coating and the body, and strengthen the protective performance of the coating. Ferrous metals should be phosphating before removal and non-ferrous metals should be oxidized before coating.

Be bored with child layer: to rough uneven airframe, use be bored with child layer to have a lot of shortcomings, such as construction trouble, reduce the binding force of coating and airframe.

The main purpose of the top coat is to add gloss to the product and is applied to the outermost layer of the coating.

The process flow

The workpiece passes through the conveyor chain to the gun position in the duster room to prepare for the spraying operation. Electrostatic generator through the nozzle electrode needle to the direction of the workpiece space release high voltage static electricity (negative), the high voltage static electricity from. A mixture of powder and compressed air from the nozzle and ionized (negatively charged) air around the electrode.

The workpiece is connected by conveying through the hanging device (grounding pole), so that an electric field is formed between the spray gun and the workpiece. The powder reaches the workpiece surface under the double push of electric field force and compressed air pressure, and forms a uniform coating on the surface of the workpiece by electrostatic attraction.

Product detail pictures:

Related Product Guide:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by providing worth added design and style, world-class producing, and repair capabilities for China Manufacturer for Dining Table Frame - Customized Sheet Metal Enclosure Powder Coating Service – LAMBERT , The product will supply to all over the world, such as: Myanmar, Chile, Poland, Besides strong technical strength, we also introduce advanced equipment for inspection and conduct strict management. All the staff of our company welcome friends both at home and abroad to come for visits and business on the basis of equality and mutual benefit. If you are interested in any of our items, please feel free to contact us for quotation and product details.

Lambert sheet metal custom processing solutions provider.

With ten years of experience in foreign trade, we specialise in high precision sheet metal processing parts, laser cutting, sheet metal bending, metal brackets, sheet metal chassis shells, chassis power supply housings, etc. We are proficient in various surface treatments, brushing, polishing, sandblasting, spraying, plating, which can be applied to commercial designs, ports, bridges, infrastructure, buildings, hotels, various piping systems, etc. We have advanced processing equipment and a professional technical team of over 60 people to provide high quality and efficient processing services to our customers. We are able to produce sheet metal components of various shapes to meet our customers’ complete machining needs. We are constantly innovating and optimising our processes to ensure quality and delivery, and we are always “customer focused” to provide our customers with quality service and help them achieve success. We look forward to building long-term relationships with our customers in all areas!

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.