China wholesale Metal Pipe Parts - 2D 3D Exhaust Stainless Steel Pipe Tube Bending Service – LAMBERT

China wholesale Metal Pipe Parts - 2D 3D Exhaust Stainless Steel Pipe Tube Bending Service – LAMBERT Detail:

Detail Information

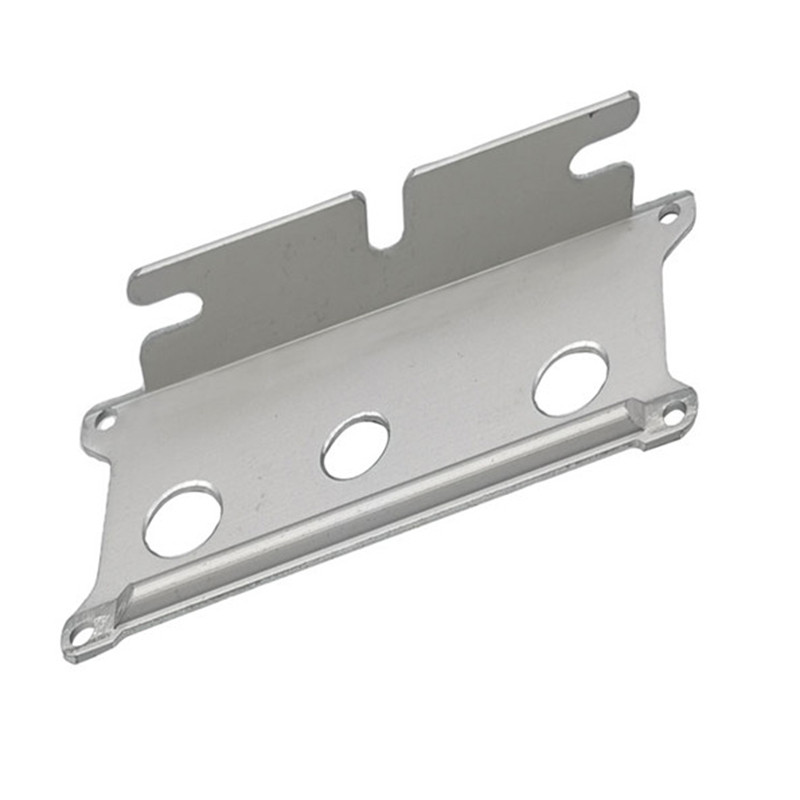

| Keywords: | exhaust pipe, Car exhaust pipe, stainless steel 304 pipe exhaust, exhaust tubes,kitchen exhaust pipe | Materials: | Sus Plate, Aluminum, Iron, brass, alloy, etc. |

| Thickness: | 0.2-1.5mm, According To Customer Request. | Tolerance: | Laser Cutting: ±0.1mm, Welding: ± 0.5mm, Tube bending: ± 0.2mm |

| Shape: | According To Customer’s Drawing Or Request | Size: | Customized Size |

| Application: | Cars, motorcycles, chimneys, drains, others | Drawing Accepted: | All Formats(UG,ProE, Auto Cad, Solidworks, And So On) |

| Machining: | Laser Cutting, Bending,welding, Polishing,chrome, Etc. | Finish: | Chrome, Powder Coating, Black And Other Color Drawing |

| Type: | Auto parts, equipment parts | Service Mode: | OEM Customized |

| Standard: | Custom High Precision Non-Standard | Surface treatment: | Powder coating,chrome,polish,hot dip zinc |

Short Description

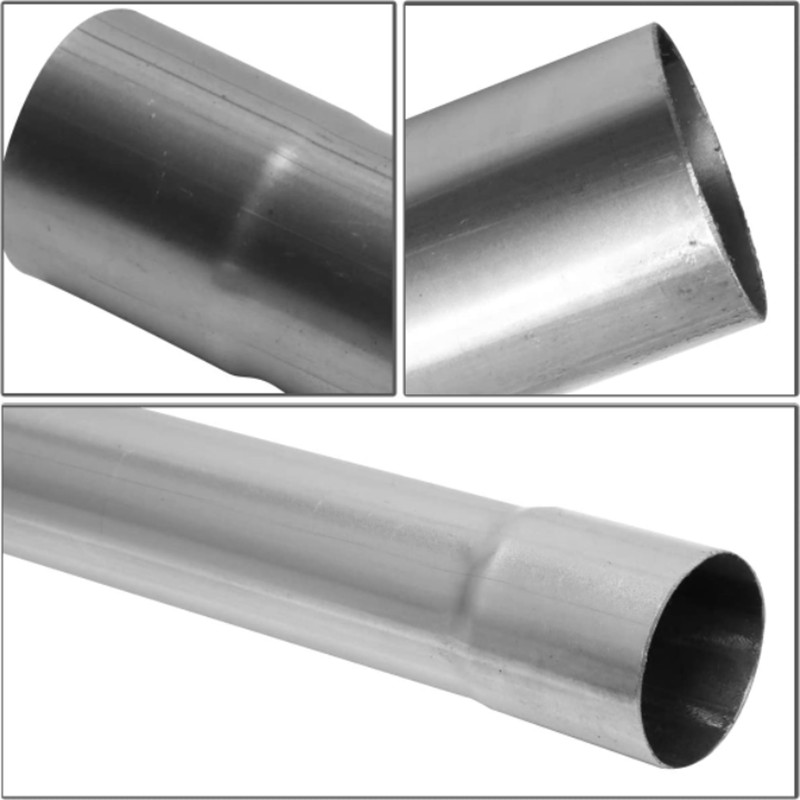

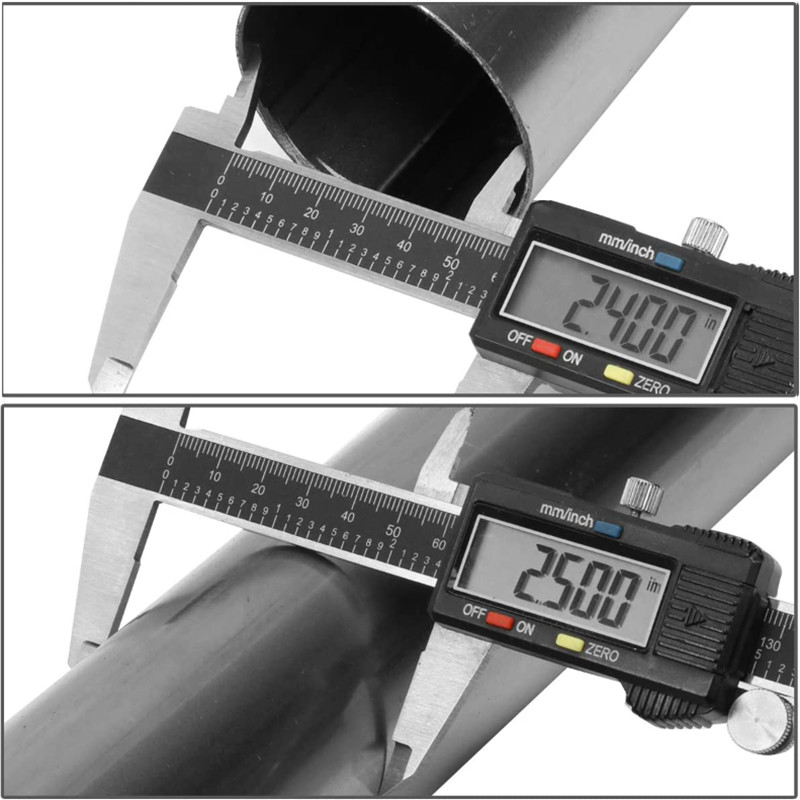

Specification: No. 16 Wall, inlet/outlet size (in):2.5″ outer diameter

Ease of use: Sliding joints provide the simplest method of manufacturing

Currency sets :48″ straight tubes, 4 90 “tubes, 4 45″ tubes, and 4 180 “u-shape tubes

Sturdy structure: manufactured with high-quality low-carbon steel,computer-controlled core shaft strength and durability, increasing exhaust wind rate to the maximum

Customization: This set of exhaust bends contains enough tubes to run the exhaust system any way you want

Product Description

100% new project. No instructions are included. Professional instorers are highly recommended. * This product is not created or sold by either brand of train.

Universal Kit

Item Specification

1.Custom: These exhaust throttling kits contain enough tubes to operate your own exhaust system.

2.Easy To Use: Slip Fit Joints to Provide Easiest Fabrication

3.Sturdy Structure:Made of High Quality Mild Steel with Computerized Mandrel-Bends for Strength and Durability, i.e. Maximizing Smoothest High Exhaust Air Flow Rate

4.Specification: 16-Gauge Piping Walls, Inlet / Outlet Size (IN) : 2.5″ OD

Importance of Wastegates

Importance of exhaust leakage Valve

The exhaust gas gate is a type of valve, a turbocharger system that releases exhaust gas from the turbine wheels.

The classification of exhaust gas controls the number of turns of the turbine, controls the number of turns of the compressor. The primary role of the exhaust gas gate is to regulate the maximum overpressure pressure of the turbocharger system to protect the engine and the turbocharger. One of the advantages of installing a remote installed exhaust gate in a free-float (or non-WG) turbine is that it allows for a smaller A/R turbine housing and reduces hysteresis from cirrus initiation of the turbine to lift generation.

Product detail pictures:

Related Product Guide:

We now have our own gross sales team, style and design workforce, technical crew, QC workforce and package group. We now have strict quality manage procedures for each system. Also, all of our workers are experienced in printing industry for China wholesale Metal Pipe Parts - 2D 3D Exhaust Stainless Steel Pipe Tube Bending Service – LAMBERT , The product will supply to all over the world, such as: South Korea, Myanmar, Malaysia, Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant professional knowledge, to develop advanced production equipment and production process , to create the first-call quality products, reasonable price , high quality of service , quick delivery , to give you create new value .

Lambert sheet metal custom processing solutions provider.

With ten years of experience in foreign trade, we specialise in high precision sheet metal processing parts, laser cutting, sheet metal bending, metal brackets, sheet metal chassis shells, chassis power supply housings, etc. We are proficient in various surface treatments, brushing, polishing, sandblasting, spraying, plating, which can be applied to commercial designs, ports, bridges, infrastructure, buildings, hotels, various piping systems, etc. We have advanced processing equipment and a professional technical team of over 60 people to provide high quality and efficient processing services to our customers. We are able to produce sheet metal components of various shapes to meet our customers’ complete machining needs. We are constantly innovating and optimising our processes to ensure quality and delivery, and we are always “customer focused” to provide our customers with quality service and help them achieve success. We look forward to building long-term relationships with our customers in all areas!

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.