Chinese Professional Tube Laser Cutting Services - Custom High Quality Acrylic Sheets Laser Cutting service – LAMBERT

Chinese Professional Tube Laser Cutting Services - Custom High Quality Acrylic Sheets Laser Cutting service – LAMBERT Detail:

Short Description

Acrylic, also known as PMMA or plexiglass, chemical name for poly methyl methacrylate. It is an important plastic polymer material developed earlier, with good transparency, chemical stability and weather resistance, easy to dye, easy to process, beautiful appearance, widely used in the construction industry. Plexiglass products can usually be divided into cast plate, extruded plate and molded plastic. Acrylic products are acrylic board, acrylic plastic granules, acrylic light box, signs, acrylic bathtub, acrylic artificial marble, acrylic resin, acrylic (latex) paint, acrylic adhesive and so on, a wide variety of products.

There is acrylic tolerance in the thickness of acrylic sheet, so the control of acrylic tolerance is an important embodiment of quality management and production technology. Acrylic production has an international standard ISO.

Casting plate tolerance requirements: Tolerance =± (0.4 + 0.1x thickness)

Extrusion plate tolerance requirements: tolerance =< 3 mm thickness :± 10% > 3 mm thickness :± 5 %.

Product Description

Acrylic laser cutting machine is generally limited to the thickness of the material, domestic laser tube power is generally in the following 400 watts of processing material thickness in the following 40mm. In a broad sense, the power of the laser tube determines the thickness of the processing material. Sometimes, customers need to add paper or film cutting, when the wind can not be too low, or it will catch fire. When cutting plexiglass speed and light intensity must be matched, the slower the speed, the smoothness is not the better. 15mm above the plexiglass had better use imported high-power laser. Plexiglass sculpture with air leakage jet cup, try not to carve too deep, too deep carving is difficult to achieve the bottom flatness, the more gas will affect the edge of the sculpture effect, to carve more fine and clear, can not be too deep and blowing stingy.

Product detail pictures:

Related Product Guide:

Our company insists all along the quality policy of "product good quality is base of enterprise survival; buyer fulfillment will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" and also the consistent purpose of "reputation very first, shopper first" for Chinese Professional Tube Laser Cutting Services - Custom High Quality Acrylic Sheets Laser Cutting service – LAMBERT , The product will supply to all over the world, such as: Austria, Belize, Rotterdam, Our products are widely sold to Europe, USA, Russia, UK, France, Australia, Middle East, South America, Africa, and Southeast Asia, etc. Our products are highly recognized by our customers from all around the world. And our company is committed to continually improving effectiveness of our management system to maximize customer satisfaction. We sincerely hope to make progress with our customers and create a win-win future together. Welcome to join us for business!

Lambert sheet metal custom processing solutions provider.

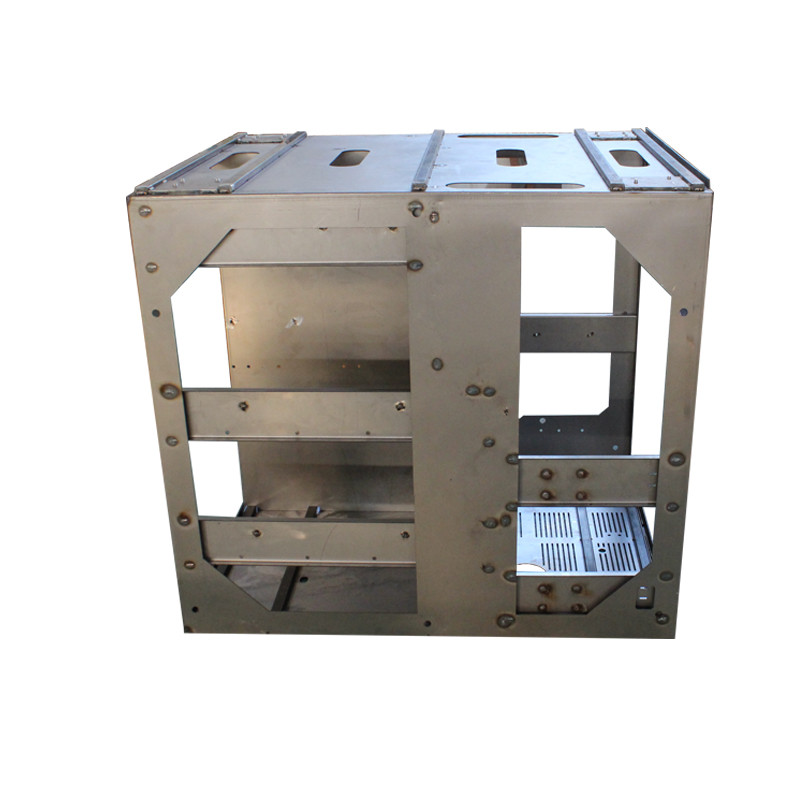

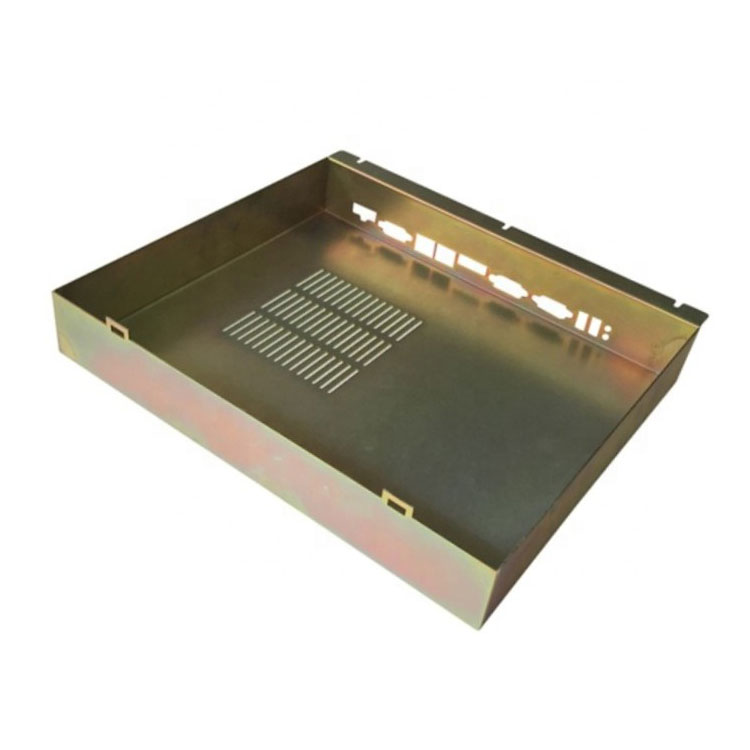

With ten years of experience in foreign trade, we specialise in high precision sheet metal processing parts, laser cutting, sheet metal bending, metal brackets, sheet metal chassis shells, chassis power supply housings, etc. We are proficient in various surface treatments, brushing, polishing, sandblasting, spraying, plating, which can be applied to commercial designs, ports, bridges, infrastructure, buildings, hotels, various piping systems, etc. We have advanced processing equipment and a professional technical team of over 60 people to provide high quality and efficient processing services to our customers. We are able to produce sheet metal components of various shapes to meet our customers’ complete machining needs. We are constantly innovating and optimising our processes to ensure quality and delivery, and we are always “customer focused” to provide our customers with quality service and help them achieve success. We look forward to building long-term relationships with our customers in all areas!

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!