Customized processing and our advantages

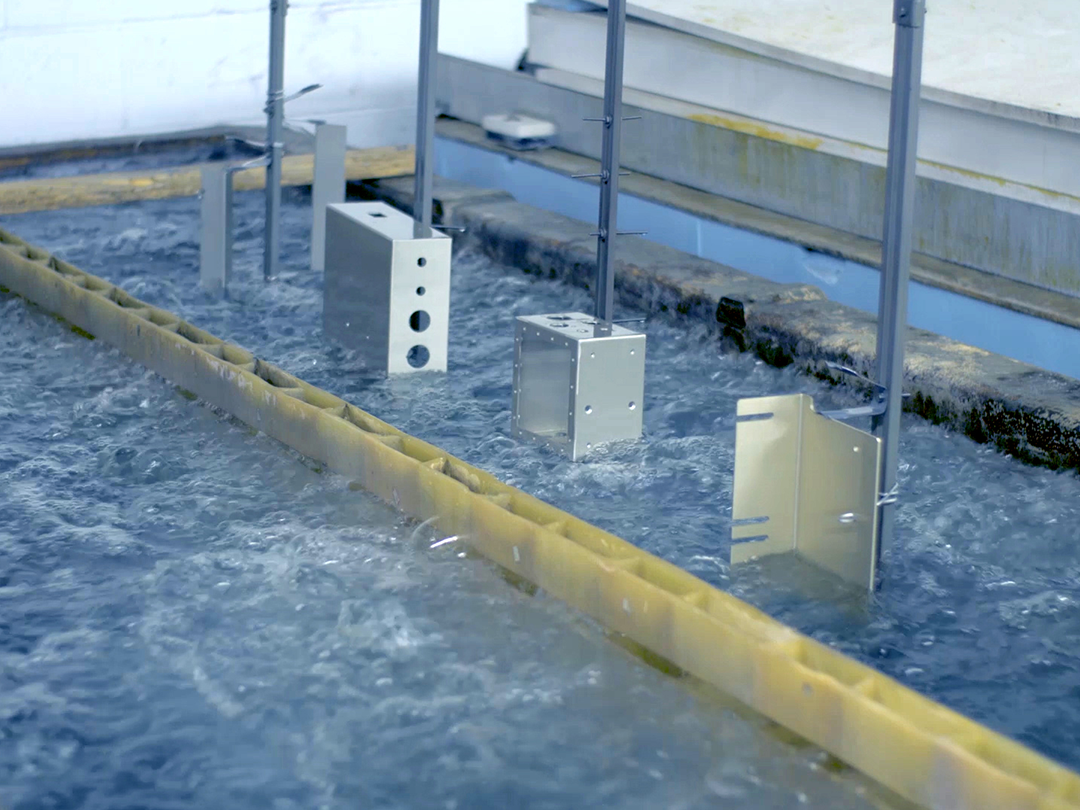

Zhongshan Lambert Precision Hardware Co., Ltd. is a foreign trade factory specializing in customized processing. We provide OEM, ODM and custom processing services. Our products are of high quality and competitive price. Our main customers are from the middle and high-end markets in Europe, Australia and America.

Our company was founded in 2012. We have been focusing on sheet metal processing. We have experienced designers and technicians, and skilled production workers. We have advanced processing equipment, and our processing accuracy reaches ± 0.02mm. We have very strict requirements for the surface of our products. Our products are highly praised by customers for their high-precision size and perfect surface treatment look like the artworks.

We have the following main processing equipment.

Laser cutting metal plate

The sheet metal laser cutting machine is a high precision cutting machine that is widely

used in the metalworking industry. It uses a laser beam to cut metal materials and has

the advantages of high precision, high speed cutting, flexibility, contactless cutting

and automatic control, making it an indispensable piece of equipment in the modern

metalworking industry

3D pipe cutting

These machines can cut various round, square, flat and irregular tubes in precision:

- - Iron pipe

- - Galvanized pipe

- - AISI 430 tube

- - AISI 304 tube

- THINKNESS: 0.2mm - 50mm

- MAX SIZE: φ220mm*6000 mm

- TOLERANCE: ±0.05mm

Sheet metal bending machines

Sheet metal bending machine is a kind of machinery and equipment specially

designed for processing sheet metal materials. Sheet metal bending machine

has the advantages of high efficiency, high precision, flexibility, saving human

resources and improving product quality. It has a wide range of applications

and can meet the needs of different industries and fields for sheet metal processing

Robot welding

A robotic TIG (Tungsten Inert Gas) welding center. A robotic MIG (Metal-arc Inert Gas) welding center. Combined with various special fixtures, we can process various complex parts. We can even use automatic welding technology inside the box

Laser cutting machines for sheet metal

With high speed, high precision, high flexibility, low burr and high productivity, sheet metal laser cutting machines are widely used in the sheet metal processing field to improve processing efficiency and product quality

Laser tube cutter

The sheet metal laser tube cutter is an efficient and precise machine designed for cutting metal tubes. It features high speed cutting, high precision and adaptability,enabling fast completion of the cutting task and guaranteeing the quality and accuracy of the cut surface

3D drawing design

With 3D design drawings, manufacturers can check the suitability and manufacturability of their products in advance, optimise design solutions, reduce production costs and ensure the quality and precision of the final product.

We can provide various high-quality surface treatments. For example: grinding, polishing, wire drawing, electroplating, powder spraying, anodizing, etc.

Sheet metal welding is a process in which two or more sheet metal workpieces are joined by heat or pressure. It is used to join thin sheets of metal and is commonly used in the manufacture of metal structures, components and containers etc. A variety of methods can be used for sheet metal welding, including stud welding, fillet welding, spot welding and laser welding.

Polishing: Grinding and polishing of sheet metal surfaces using abrasive tools and abrasives to make the surface smooth, flat and shiny

Sandblasting: A high pressure sandblaster is used to blast sand onto the sheet metal surface to remove surface oxidation, stains and burrs through abrasion and impact, making the surface smooth and uniform.

Spraying: Using a spray gun, paint is applied to the surface of sheet metal products for protection and beautification. Spraying can be done with different types of paint such as lacquer, powder coating etc.

The appearance, corrosion resistance and mechanical properties of sheet metal can be improved by anodising. Anodising usually includes process steps such as pickling and cleaning, electrolytic oxidation and sealing treatment.

Sheet metal plating is a common surface treatment process to increase the corrosion resistance, aesthetics and electrical conductivity of sheet metal by coating it with a thin layer of metal or alloy.

We are a professional custom factory, which can meet the needs of various sizes, materials and surface treatment. We are committed to creating a win-win situation. If you have projects or ideas, please feel free to contact us. You can trust us to produce the products. Your team can focus on marketing and achieve higher efficiency.