Factory Cheap Hot Brass Cnc Machining - Custom High Precision Lathe turning Cnc machining service – LAMBERT

Factory Cheap Hot Brass Cnc Machining - Custom High Precision Lathe turning Cnc machining service – LAMBERT Detail:

Short Description

1. 5 models of hard alloy cutter satisfy all requirements. : 11mm angular radius including 2; two 12mm and 8.9mm circular tubes;30mm and 28mm with a rhomboid tip at one point each. To supply (a screw).

2. Scope of application: Apply to perfect finish bending, jointing, jointing work and ordinary wood linings. This combination provides an alternative to hard alloy knives for the vast majority of woodworking sharpening tools.

3. Durable tungsten steel material: Made from tungsten steel, providing the optimum combination of sharpness and durability. Trim with mirror face finish to ensure smooth cutting and longer tool life.

4. Suitable for each class of woodworking. : This is one free combination suit which can meet the demand of conditioning and chastity. Suitable for professional carpenters or beginners.

Product Description

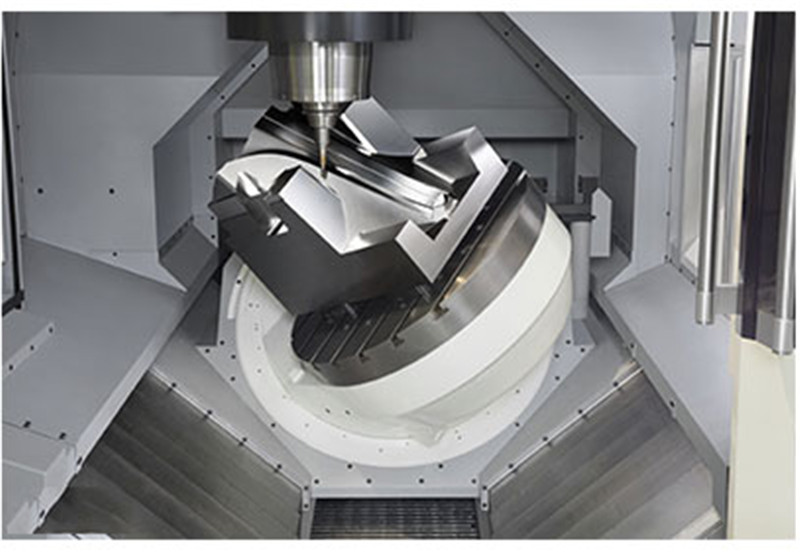

5 axis machining center

High precision,complex shape,Low surface roughness,high efficiency and low cost.Tolerance : ±0.01mm

| item | value |

| Name | OEM custom CNC lathe turning processing service, CNC metal parts. |

| Material | Satinless steel,iron,aluminum,alloy,brass etc. |

| Tolerance | ±0.02mm |

| Size or shape | According to customer drawing or request |

| Application | Used Widely |

| Drawing accepted | All formats. Such as: cad, pdf, solidWorks,proE,ug,etc. |

| Machining | Laser cutting, cnc punching, bending, turning, milling, reviting, welding, polishing, assembly |

| Quality Control | ISO 9001,100% QC Test before shipment. |

| Surface treatment | Polishing, brushing, chrome,painting, powder coating,hot dip,spraying etc. |

| Delivery Time | 7-30 days |

| Service mode | OEM or ODM, customized |

| Certificate | ISO 9001 |

| Feature or advantage | R&D ability, FREE design, All in one solution.cost reduction. |

| Experience | OEM & ODM since 2012 |

NOTE: We have advanced equipments and experienced team. We always adhere to the improvement of production technology, committed to providing high quality products and efficient service.

Our services include: customized finished products, 3D printing, various metal products, spare parts,various sheet and tube profile processing, various products and spare parts’s surface treatment.

Product detail pictures:

Related Product Guide:

With this motto in mind, we have turn out to be amongst probably the most technologically innovative, cost-efficient, and price-competitive manufacturers for Factory Cheap Hot Brass Cnc Machining - Custom High Precision Lathe turning Cnc machining service – LAMBERT , The product will supply to all over the world, such as: Sri Lanka, Greece, Mauritania, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our items and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

Lambert sheet metal custom processing solutions provider.

With ten years of experience in foreign trade, we specialise in high precision sheet metal processing parts, laser cutting, sheet metal bending, metal brackets, sheet metal chassis shells, chassis power supply housings, etc. We are proficient in various surface treatments, brushing, polishing, sandblasting, spraying, plating, which can be applied to commercial designs, ports, bridges, infrastructure, buildings, hotels, various piping systems, etc. We have advanced processing equipment and a professional technical team of over 60 people to provide high quality and efficient processing services to our customers. We are able to produce sheet metal components of various shapes to meet our customers’ complete machining needs. We are constantly innovating and optimising our processes to ensure quality and delivery, and we are always “customer focused” to provide our customers with quality service and help them achieve success. We look forward to building long-term relationships with our customers in all areas!

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.