Factory Cheap Hot Large Laser Cutting Service - Custom Processing Sheet Metal Laser Cutting Service – LAMBERT

Factory Cheap Hot Large Laser Cutting Service - Custom Processing Sheet Metal Laser Cutting Service – LAMBERT Detail:

Short Description

Sheet metal, a processing process, sheet metal has not yet a relatively complete definition. According to a definition in a foreign professional journal, it can be defined as: sheet metal is for metal sheet (usually below 6mm) a comprehensive cold processing process, including shear, punching/cutting/composite, folding, riveting, splicing, forming (such as car body), etc.. Its remarkable feature is the same thickness of the same part.

Sheet metal has the characteristics of light weight, high strength, electric conductivity (can be used for electromagnetic shielding), low cost, good mass production performance, etc., in electronic appliances, communications, automotive industry, medical equipment and other fields have been widely used, such as in computer cases, mobile phones, MP3, sheet metal is an essential part. With the application of sheet metal more and more widely, sheet metal parts design has become a very important part of the product development process, mechanical engineers must master the design skills of sheet metal parts, make the design of sheet metal not only meet the function and appearance of the product requirements, but also make the stamping die manufacturing simple, low cost.

Product Description

Most laser cutting machines are controlled by CNC programs or made into cutting robots. Laser cutting as a precision processing method, almost all materials can be cut, including thin metal plate two-dimensional cutting or three-dimensional cutting.

Laser cutting forming technology is also widely used in the field of non-metallic materials. Can not only cut high hardness, brittle materials, such as silicon nitride, ceramics, quartz, etc.; It can also cut and process flexible materials, such as cloth, paper, plastic board, rubber, etc., such as clothing cutting with laser, can save 10% ~ 12% of clothing material, improve the efficacy of more than 3 times.

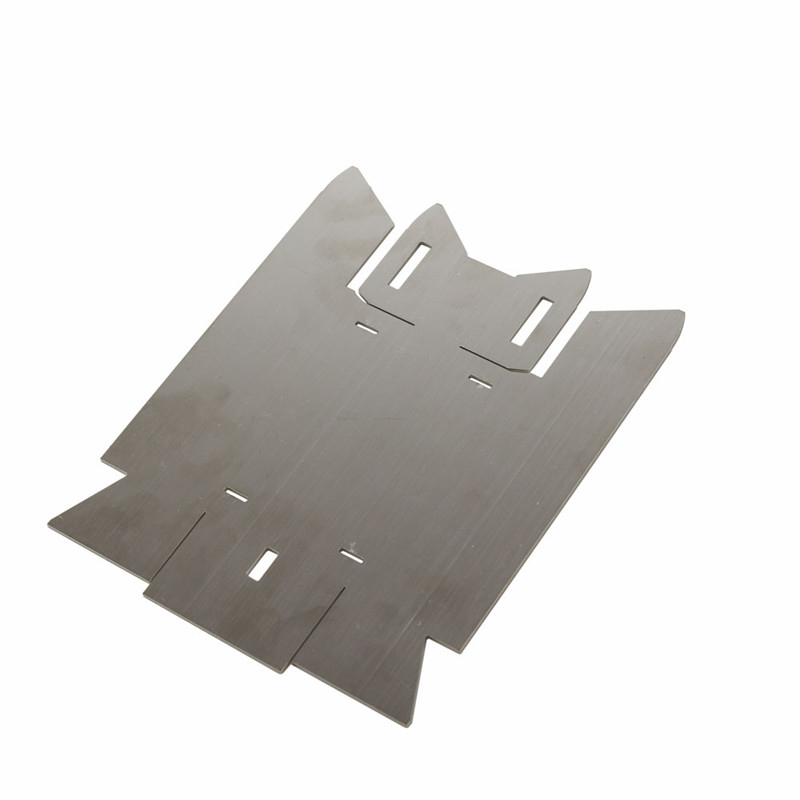

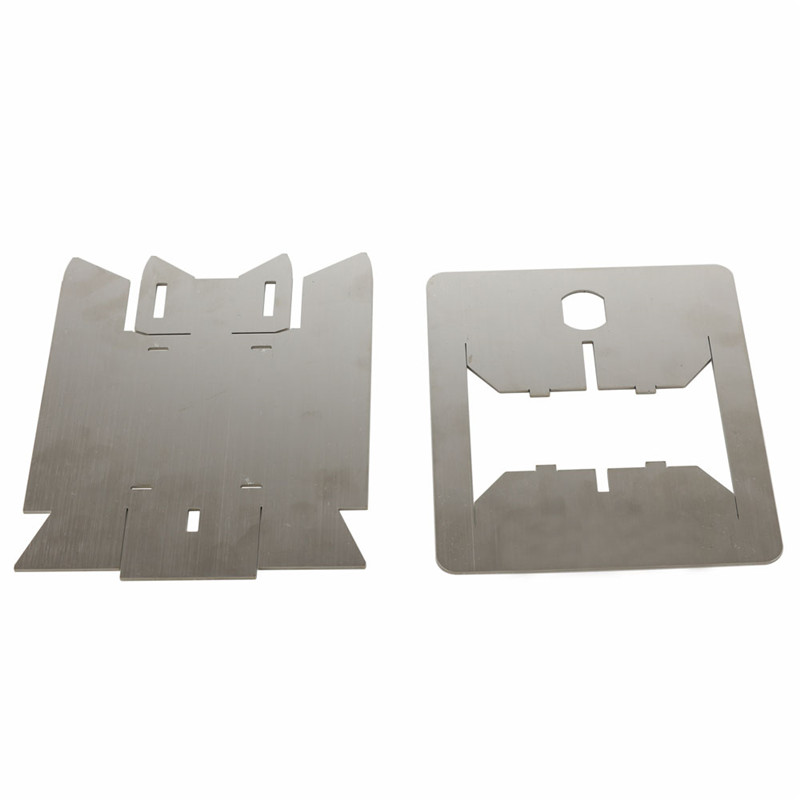

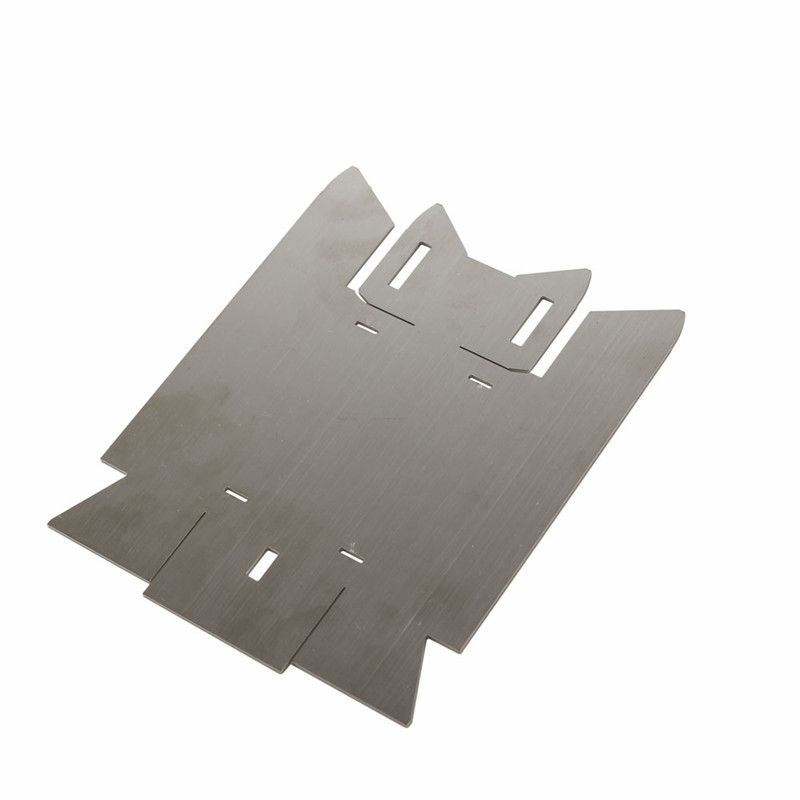

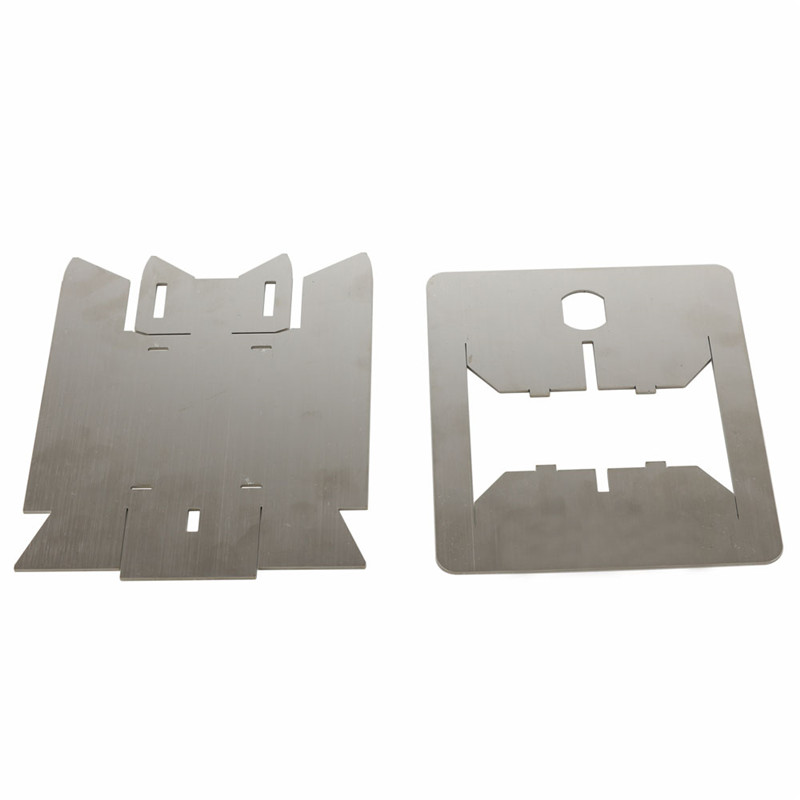

Product detail pictures:

Related Product Guide:

We support our prospective buyers with ideal top quality merchandise and superior level provider. Becoming the specialist manufacturer in this sector, we have now attained abundant practical expertise in producing and managing for Factory Cheap Hot Large Laser Cutting Service - Custom Processing Sheet Metal Laser Cutting Service – LAMBERT , The product will supply to all over the world, such as: Liberia, Lyon, Bangkok, We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

Lambert sheet metal custom processing solutions provider.

With ten years of experience in foreign trade, we specialise in high precision sheet metal processing parts, laser cutting, sheet metal bending, metal brackets, sheet metal chassis shells, chassis power supply housings, etc. We are proficient in various surface treatments, brushing, polishing, sandblasting, spraying, plating, which can be applied to commercial designs, ports, bridges, infrastructure, buildings, hotels, various piping systems, etc. We have advanced processing equipment and a professional technical team of over 60 people to provide high quality and efficient processing services to our customers. We are able to produce sheet metal components of various shapes to meet our customers’ complete machining needs. We are constantly innovating and optimising our processes to ensure quality and delivery, and we are always “customer focused” to provide our customers with quality service and help them achieve success. We look forward to building long-term relationships with our customers in all areas!

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.