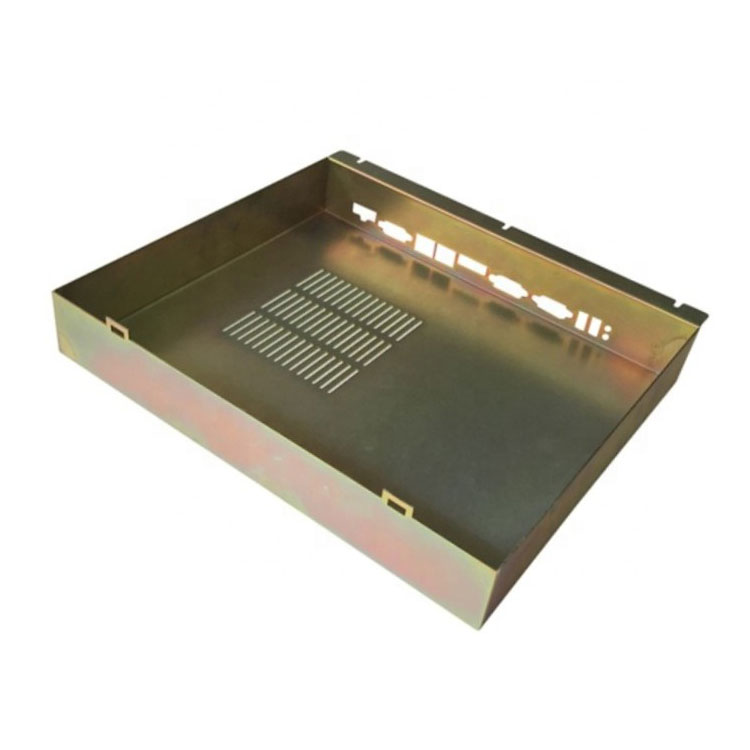

Factory selling Distribution Box Electrical - Custom Sheet Metal Fabrication wire drawing processing – LAMBERT

Factory selling Distribution Box Electrical - Custom Sheet Metal Fabrication wire drawing processing – LAMBERT Detail:

Short Description

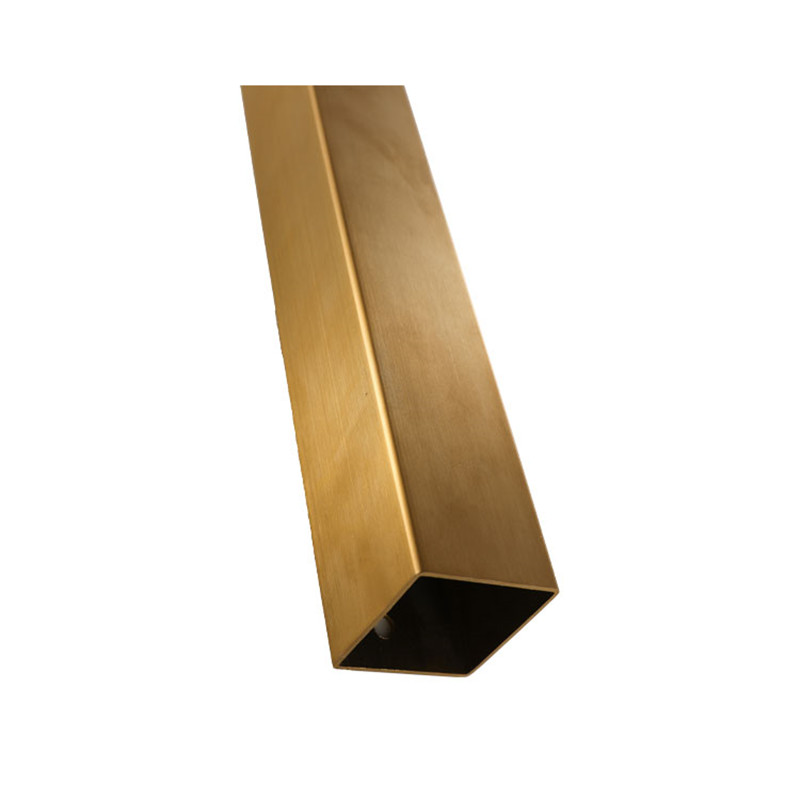

Brushed processing can also be called sweep sand, sweep nylon, and so on. Usually according to the surface effect is divided into straight silk and disorderly silk. Straight silk is also called hair silk, messy silk is also called snow pattern, silk type has a great subjectivity. Each user has different requirements for surface lines and different preferences for line lines. Some people think hair is beautiful, some people like snow pattern, some like long hair, some like short hair. Due to the variety of wire effect, it is usually difficult to describe and define, but by determining the processing method of wire drawing, grinding products used, process parameters and other ways to determine the wire effect.

Wiredrawing processing can make the metal surface to obtain the mirror metallic luster, like silk, satin, have very strong adornment effect as to the ordinary metal to the new life and the life, so the wiredrawing processing has more and more market recognition and wide application of elevator door plank, escalator decorating plate in the construction industry, in building hardware industry bibcock, hinges, handles, locks plaques, And so on; Cabinet is provided if smoke lampblack machine, stainless steel kitchen is provided, cistern is waited a moment

Product Description

Surface drawing is a surface treatment method which forms lines on the surface of the workpiece by grinding the product and plays a decorative effect.

Folding flat pressing sand belt drawing

Polishing can be used to enhance and restore the appearance of certain metal parts or objects on automobiles and other vehicles, handrails, cookware, kitchenware and construction metal.

Nonwoven cloth is brushed by roller

The workpiece is transferred by conveyor belt through nonwoven roller brush, which rotates at high speed to draw the workpiece surface. When drawing, roller brush vibration and roller brush vibration can be used in two ways, at the same time with different processing speed to produce different length of line lines. Nonwoven roller brush vibration, can produce very uniform and consistent discontinuous silk (short silk); Non-woven roller brush does not vibrate, can produce continuous silk lines (filament or straight silk).

Fold wide sand belt for wire drawing

This drawing method is the most traditional drawing method, used for flat drawing, especially suitable for plate processing. The belt rotates at a high speed, and the plate is polished and brushed by the conveyor belt through the belt. Usually, stainless steel plate, aluminum alloy and other plates are made into semi-finished drawing products, so as to further produce products with plates as raw materials, such as stainless steel elevator drawing door, stainless steel counter, aluminum alloy chassis, etc. The lines drawn in this way are usually very thin and short, and can be called snow patterns. In this way, it is required that the service of sand belt is better, and the line effect of plate can be more uniform. 3M’s nonwoven belts offer better adhesion than traditional coated belts.

Folding centerless grinding wire drawing

This is the way of wire drawing by centerless grinding. The abrasive products used are non-woven fabric drawing wheels or belts. Suitable for round tubular workpiece, such as handle. This way of drawing lines are usually short silk lines, silk lines and the length of the workpiece rotation speed, grinding product rotation speed and grinding product itself.

The folding polisher draws the wire

Just use the machine speed drive nylon wheel, through artificial technology for grinding products. Suitable for irregular electroplating products.

Product detail pictures:

Related Product Guide:

Our items are commonly identified and trusted by people and can fulfill repeatedly altering economic and social wants of Factory selling Distribution Box Electrical - Custom Sheet Metal Fabrication wire drawing processing – LAMBERT , The product will supply to all over the world, such as: The Swiss, Austria, Bangladesh, Now, with the development of internet, and the trend of internationalization, we have decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to give our customers more profit, and looking forward to more chance to make business.

Lambert sheet metal custom processing solutions provider.

With ten years of experience in foreign trade, we specialise in high precision sheet metal processing parts, laser cutting, sheet metal bending, metal brackets, sheet metal chassis shells, chassis power supply housings, etc. We are proficient in various surface treatments, brushing, polishing, sandblasting, spraying, plating, which can be applied to commercial designs, ports, bridges, infrastructure, buildings, hotels, various piping systems, etc. We have advanced processing equipment and a professional technical team of over 60 people to provide high quality and efficient processing services to our customers. We are able to produce sheet metal components of various shapes to meet our customers’ complete machining needs. We are constantly innovating and optimising our processes to ensure quality and delivery, and we are always “customer focused” to provide our customers with quality service and help them achieve success. We look forward to building long-term relationships with our customers in all areas!

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.