Featured

-

High Quality Charcoal Grill - Custom Aluminium Iron Carbon Steel Casting / forging Service – LAMBERT

Product Description Classification of the casting There are many classification methods for castings: according to the different metal materials used, they are divided into steel castings, cast iron castings, copper castings, aluminum castings, magnesium castings, zinc castings, titanium castings and so on. Each type of casting can be further divided into different types according to its chemical composition or metallographic structure. For example, cast iron can be divided into gray cast iro... -

Factory source Metal Rack - Custom Precision Aluminum Stainless Steel Polishing service – LAMBERT

Short Description Polishing and polishing is a finishing process that uses abrasives and work wheels or leather belts to make the surface of the workpiece smooth. Technically, polishing refers to the process of using abrasives that are glued to the working wheel, while polishing uses loose abrasives that are applied to the working wheel. Polishing is a more aggressive process, while polishing is less rough, resulting in smoother, brighter surfaces. A common misconception is that polished surf... -

Low MOQ for Wholesale Table Legs - Custom Aluminium Iron Carbon Steel Casting / forging Service – LAMBERT

Product Description Classification of the casting There are many classification methods for castings: according to the different metal materials used, they are divided into steel castings, cast iron castings, copper castings, aluminum castings, magnesium castings, zinc castings, titanium castings and so on. Each type of casting can be further divided into different types according to its chemical composition or metallographic structure. For example, cast iron can be divided into gray cast iro... -

100% Original Factory Steel Products - Custom Aluminium Iron Carbon Steel Casting / forging Service – LAMBERT

Product Description Classification of the casting There are many classification methods for castings: according to the different metal materials used, they are divided into steel castings, cast iron castings, copper castings, aluminum castings, magnesium castings, zinc castings, titanium castings and so on. Each type of casting can be further divided into different types according to its chemical composition or metallographic structure. For example, cast iron can be divided into gray cast iro... -

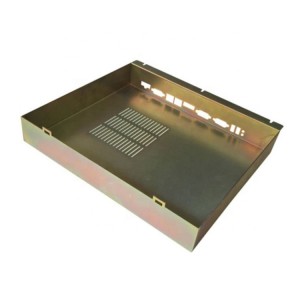

New Fashion Design for Metal Box - Customized Sheet Metal Enclosure Powder Coating Service – LAMBERT

Short Description Powder spraying process, also known as powder coating, is a new coating process developed rapidly in recent decades. The raw material used is plastic powder. Coating can get thicker coating, such as coating 100~300μm coating, with general general solvent coating, about 4~6 times, and with powder coating is once can achieve the thickness. The coating has good corrosion resistance. The powder coating does not contain solvent, and has no pollution of three wastes. Using powder ... -

Wholesale Metal Cut - Custom Processing Sheet Metal Laser Cutting Service – LAMBERT

Short Description Sheet metal, a processing process, sheet metal has not yet a relatively complete definition. According to a definition in a foreign professional journal, it can be defined as: sheet metal is for metal sheet (usually below 6mm) a comprehensive cold processing process, including shear, punching/cutting/composite, folding, riveting, splicing, forming (such as car body), etc.. Its remarkable feature is the same thickness of the same part. Sheet metal has the characteristics of l... -

High reputation Punching Metal Sheet - Wholesale custom stainless steel sheet metal table legs frames – LAMBERT

Our Advantages Competitive prices. 10 years of professional custom processing experience. 100% foreign trade factory, rich export experience. Customized and designed according to the requirements of customers. Size, material, shape, surface treatment, logo, packaging, etc. can be customized. We have laser cutting machine, numerical control bending machine, 3D bending machine, welding robot and other advanced processing equipment to meet various processing accuracy requirements. Strict q... -

PriceList for Metal Advertising Sign - Custom Stainless Steel Metal Parts welding Service – LAMBERT

Product Description Resistance welding Resistance welding is a welding method in which the workpiece is combined and pressure is applied through the electrode, and the electric current is applied through the resistance heat generated by the contact surface and adjacent area of the joint. Resistance welding is a method of heating the workpiece to a molten or plastic state by the electric current flowing through the contact surface and adjacent areas. There are four main resistance welding met... -

2022 Good Quality Custom Metal Fabrication - Stainless steel metal pipe tube CNC processing bending service – LAMBERT

Our Advantages Custom pipes bending service. Lambert precision hardware company, specializing in customized sheet metal processing. We can bend round tubes, square tubes and other tubes with special shapes. We can process stainless steel pipes, aluminum pipes, iron pipes, etc. Our machining accuracy is ± 0.2mm. Our products are suitable for many application fields such as furniture, automobile and agriculture. Item: 3D tube bending service. Thickness: 0.2-10mm, According To Customer... -

2022 wholesale price Stamping Parts - Precision customized sheet metal stamping parts – LAMBERT

Detail Information Keywords: Equipment accessories, electrical box shell, case shell, bending shell, stamping shell, sheet metal shell Materials: Sus, Aluminum,Iron,Brass,Alloy, etc. Thickness: 0.2-0.5mm, According To Customer Request. Tolerance: Laser Cutting And Bending: ±0.1mm, Stamping: ±0.02mm,Welding: ± 0.5mm Shape: According To Customer’s Drawing Or Request Size: Customized Size Application: Furniture, office, computer, refrigerator, oven, storage cabinets, cabinets, etc D... -

High Quality for Custom Fabrication Services - Wholesale custom stainless steel sheet metal table legs frames – LAMBERT

Our Advantages Competitive prices. 10 years of professional custom processing experience. 100% foreign trade factory, rich export experience. Customized and designed according to the requirements of customers. Size, material, shape, surface treatment, logo, packaging, etc. can be customized. We have laser cutting machine, numerical control bending machine, 3D bending machine, welding robot and other advanced processing equipment to meet various processing accuracy requirements. Strict q... -

2022 High quality Tube Bending - Custom CNC pipe tube bending service – LAMBERT

Short Description Pipe bending is a process in which a pipe is first loaded into a bender or pipe bender and then sandwiched between two dies (clamping block and forming die). The tube is also held loosely by two other molds, the wipe mold and the pressure mold. The tube bending process involves using mechanical forces to push the material tube or tubing against the mold, forcing the tubing or tubing to conform to the shape of the mold. Usually, the feed tube is held firmly in place as the en...