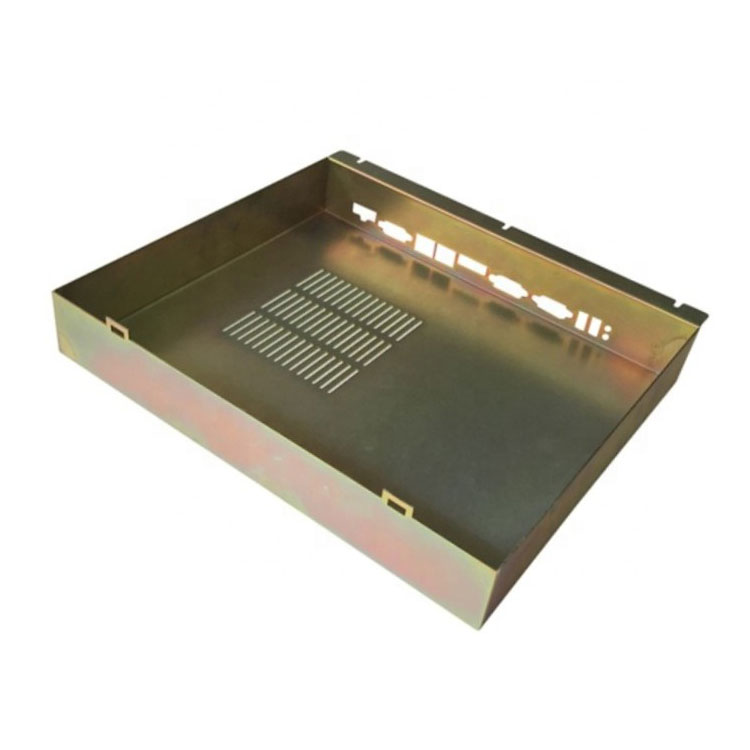

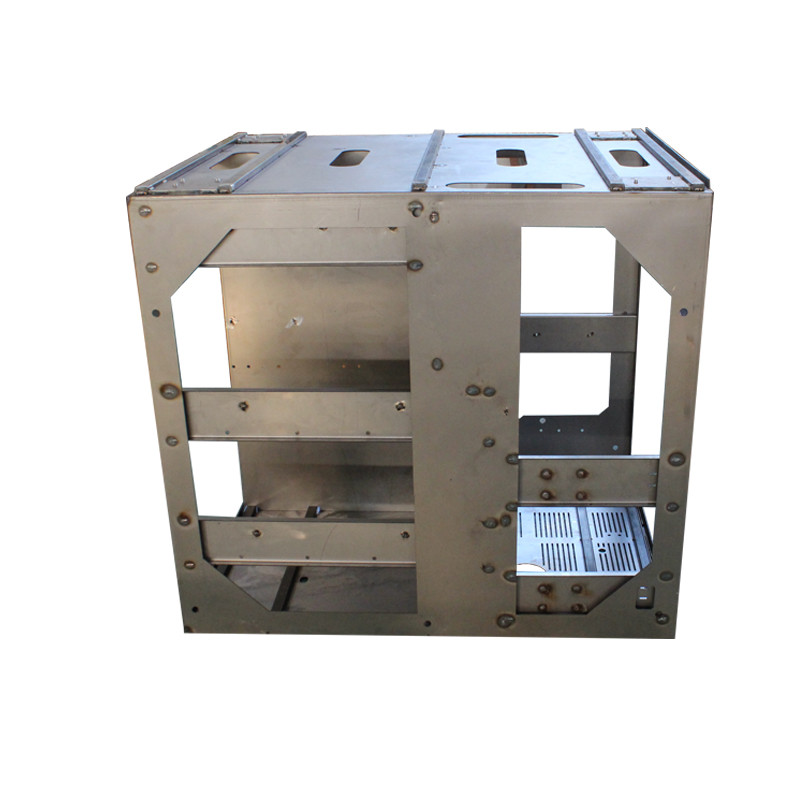

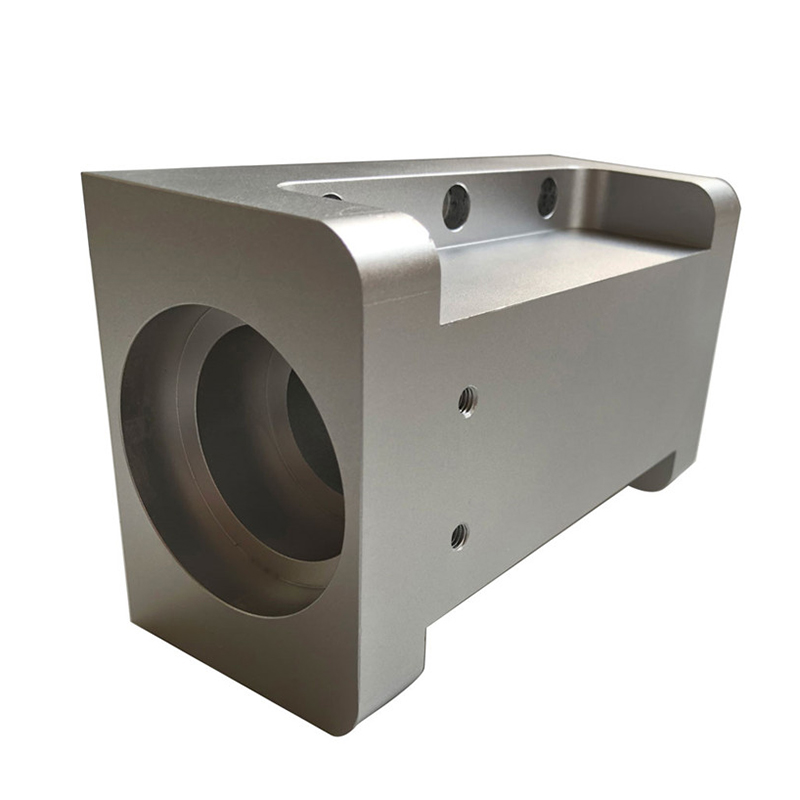

High Quality Machining Cnc - Custom-made metal Steel iron Metal Parts CNC milling Service – LAMBERT

High Quality Machining Cnc - Custom-made metal Steel iron Metal Parts CNC milling Service – LAMBERT Detail:

Short Description

(1) When turning step shaft, in order to ensure the rigidity of turning, the part with larger diameter should be turned first and the part with smaller diameter should be turned after.

(2) When cutting slots on the shaft workpiece, it should be carried out before finishing to prevent deformation of the workpiece.

(3) fine car with thread shaft, generally should be in the thread processing and then fine car without thread part.

(4) Before drilling, the end face of the workpiece should be leveled. Center holes should be made first if necessary.

(5) When drilling deep holes, the guide holes are usually drilled first.

(6) turning (φ 10-φ 20) mm hole, the diameter of the knife rod should be processed aperture 0.6-0.7 times; Processing diameter is greater than 20 mm hole, generally should be used to clamp the knife head.

(7) When turning multi-thread or multi-worm, trial cutting should be carried out after adjusting the exchange gear.

(8) when using automatic lathes, the relative position of the tool and the workpiece should be adjusted according to the machine tool adjustment card, and the trial turning should be carried out after the adjustment, and the first qualified piece can be processed; Pay attention to tool wear and workpiece size and surface roughness during machining.

(9) When turning on a vertical lathe, when the tool rest is adjusted, the beam shall not be moved at will.

(10) When the workpiece surface position tolerance requirements, try to complete the turning in a clamping.

(11) When turning the cylindrical gear blank, the hole and the reference end face must be processed in one clamping. If necessary, a marking line should be drawn near the gear indexing circle of the end face.

Product Description

| item | value |

| Name | Custom cnc milling parts machining service cnc machining items brass hot forging parts |

| Material | Satinless steel,iron,aluminum,alloy,brass etc. |

| Tolerance | ±0.02mm |

| Size or shape | According to customer drawing or request |

| Application | Used Widely |

| Drawing accepted | All formats. Such as: cad, pdf, solidWorks,proE,ug,etc. |

| Machining | Laser cutting, cnc punching, bending, turning, milling, reviting, welding, polishing, assembly |

| Quality Control | ISO 9001,100% QC Test before shipment. |

| Surface treatment | Polishing, brushing, chrome,painting, powder coating,hot dip,spraying etc. |

| Delivery Time | 7-30 days |

| Service mode | OEM or ODM, customized |

| Certificate | ISO 9001 |

| Feature or advantage | R&D ability, FREE design, All in one solution.cost reduction. |

| Experience | OEM & ODM since 2012 |

Product detail pictures:

Related Product Guide:

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our service, we provide the products with the good quality at the reasonable price for High Quality Machining Cnc - Custom-made metal Steel iron Metal Parts CNC milling Service – LAMBERT , The product will supply to all over the world, such as: Bangladesh, Egypt, Detroit, With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in this field and other industries. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success! We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

Lambert sheet metal custom processing solutions provider.

With ten years of experience in foreign trade, we specialise in high precision sheet metal processing parts, laser cutting, sheet metal bending, metal brackets, sheet metal chassis shells, chassis power supply housings, etc. We are proficient in various surface treatments, brushing, polishing, sandblasting, spraying, plating, which can be applied to commercial designs, ports, bridges, infrastructure, buildings, hotels, various piping systems, etc. We have advanced processing equipment and a professional technical team of over 60 people to provide high quality and efficient processing services to our customers. We are able to produce sheet metal components of various shapes to meet our customers’ complete machining needs. We are constantly innovating and optimising our processes to ensure quality and delivery, and we are always “customer focused” to provide our customers with quality service and help them achieve success. We look forward to building long-term relationships with our customers in all areas!

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.