Manufactur standard Sheet Metal Weld - Stainless steel metal pipe tube CNC processing bending service – LAMBERT

Manufactur standard Sheet Metal Weld - Stainless steel metal pipe tube CNC processing bending service – LAMBERT Detail:

Our Advantages

Custom pipes bending service.

Lambert precision hardware company, specializing in customized sheet metal processing. We can bend round tubes, square tubes and other tubes with special shapes. We can process stainless steel pipes, aluminum pipes, iron pipes, etc. Our machining accuracy is ± 0.2mm.

Our products are suitable for many application fields such as furniture, automobile and agriculture.

| Item: | 3D tube bending service. |

| Thickness: | 0.2-10mm, According To Customer Request. |

| Shape and Size: | Custom. According To Customer’s Drawing Or Request |

| Machining: | Bending and welding, laser cutting |

| Standard: | Custom High Precision, Non-Standard |

| Materials: | Stainless steel pipes, metal pipes. |

| Tolerance: | ±0.2mm |

| Drawing Accepted: | All Formats(UG,ProE, Auto Cad, Solidworks, And So On) |

| Surface treament | Drawing, Brushing, polishing, Chrome, Powder Coating etc. |

| Service Mode: | OEM or ODM |

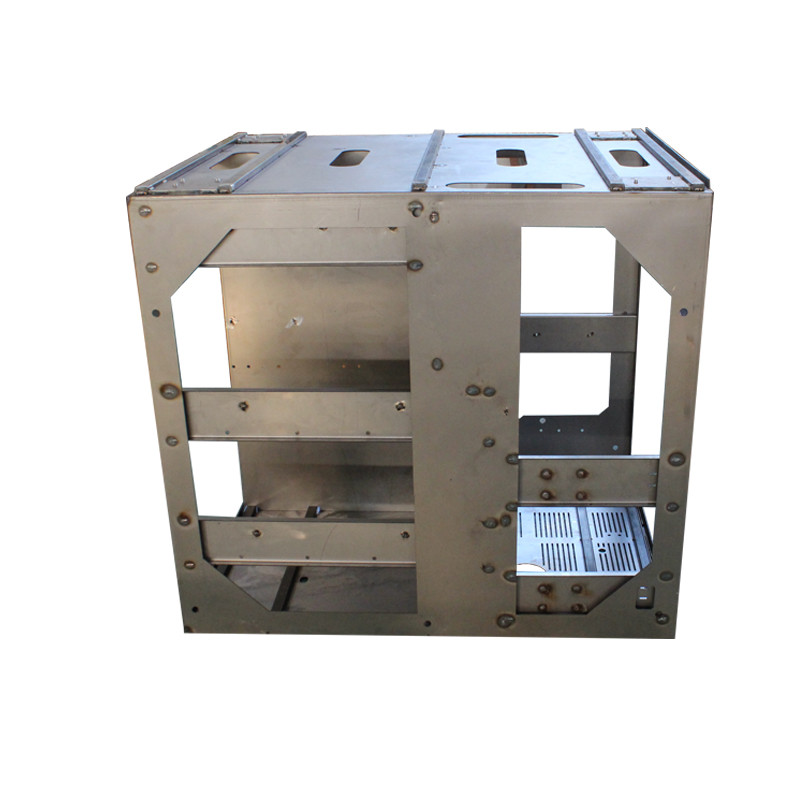

Product detail pictures:

Related Product Guide:

That has a sound small business credit, great after-sales service and modern production facilities, we've earned an outstanding standing amid our buyers across the earth for Manufactur standard Sheet Metal Weld - Stainless steel metal pipe tube CNC processing bending service – LAMBERT , The product will supply to all over the world, such as: Italy, Latvia, Kuwait, our qualify products have good reputation from the world as its most competive price and our most advantage of after-sale service to the clients.we hope we can provide a safe, environmental products and super service to our clients from all of the world and establish strategic partnership with them by our professional standards and unremitting efforts.

Lambert sheet metal custom processing solutions provider.

With ten years of experience in foreign trade, we specialise in high precision sheet metal processing parts, laser cutting, sheet metal bending, metal brackets, sheet metal chassis shells, chassis power supply housings, etc. We are proficient in various surface treatments, brushing, polishing, sandblasting, spraying, plating, which can be applied to commercial designs, ports, bridges, infrastructure, buildings, hotels, various piping systems, etc. We have advanced processing equipment and a professional technical team of over 60 people to provide high quality and efficient processing services to our customers. We are able to produce sheet metal components of various shapes to meet our customers’ complete machining needs. We are constantly innovating and optimising our processes to ensure quality and delivery, and we are always “customer focused” to provide our customers with quality service and help them achieve success. We look forward to building long-term relationships with our customers in all areas!

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.