Manufacturer for Cnc Precision Machining - Custom Cnc Compound Machining Service metal Parts – LAMBERT

Manufacturer for Cnc Precision Machining - Custom Cnc Compound Machining Service metal Parts – LAMBERT Detail:

Development History

20 century 80′s in the late period, along with the machining center function and the structure of the perfection, showed the superiority of the numerical control machine tool of this kind of working procedure concentration, began to appear turning center, grinding center and so on, so that the compound processing is extended and no longer limited to boring, milling and other working procedures. In the late 1990s, it further developed the turning milling center, milling turning center, turning grinding center, etc. In recent years, it also appeared by laser, electric spark and ultrasonic and other special processing methods and cutting, grinding processing method combination of compound machine tool, so that compound processing technology has become a new hot spot to promote the development of machine tool structure and manufacturing technology.

Compound processing machine tool highlights the workpiece in a card to complete most or all the processing process, so as to reduce the machine tools and fixtures, improve the workpiece processing accuracy, shorten the processing cycle and save the working area.

Product Description

Classification of machine tool

From the rigidity and precision of the bed

The difference with other similar products lies in that: the machine adopts the integral 60° inclined bed design, X, Y, Z axis adopts super-size linear guide rail, adopts gear drive mechanical spindle, each slide seat and spindle system is clamped by a specially designed clamping system.

X and Y axes are equipped with heidheim glass grating ruler. According to German VDI/DGQ 3441 standard, the positioning accuracy is less than 0.005mm, and the repetition accuracy can reach 0.001mm(depending on machine tool model and control axis). The WFL turn-milling complex machining center not only achieves extremely high positioning accuracy, but also measures and compensates for errors caused by unavoidable external factors, such as temperature rise of machining parts, tool wear, geometric deformation of parts, and errors caused by tools and clamping devices. Specifically to compensate for this error, WFL developed a unique software package that simultaneously converts the MILLTURN mill into a true 3D measuring machine. The measurement results can be used to correct the above errors under the same loading condition. All measurements and tool parameters can be stored on hard disk, printed directly from the machine tool or transmitted over Ethernet for further processing.

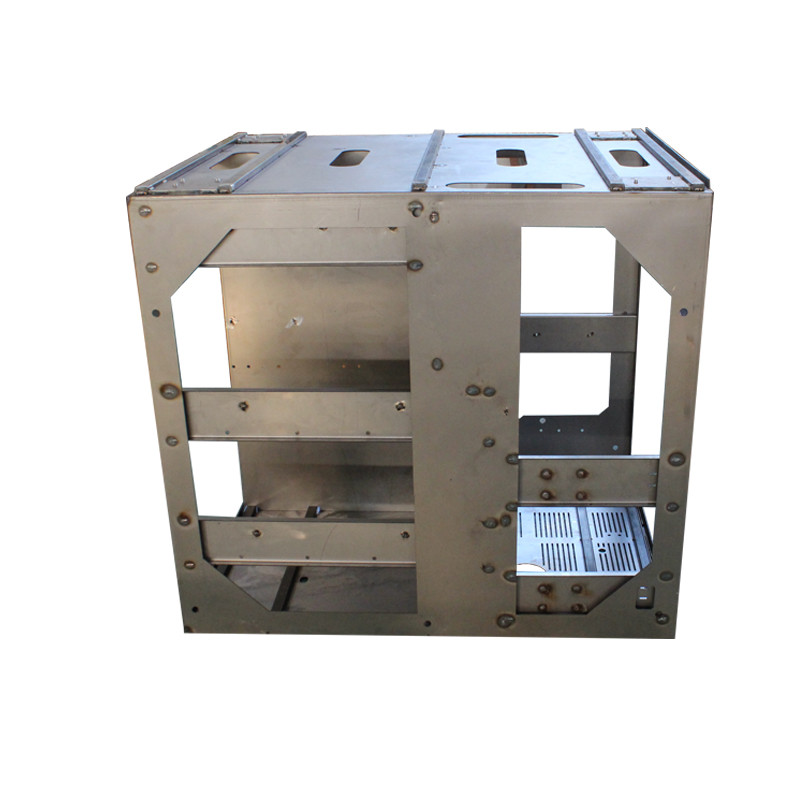

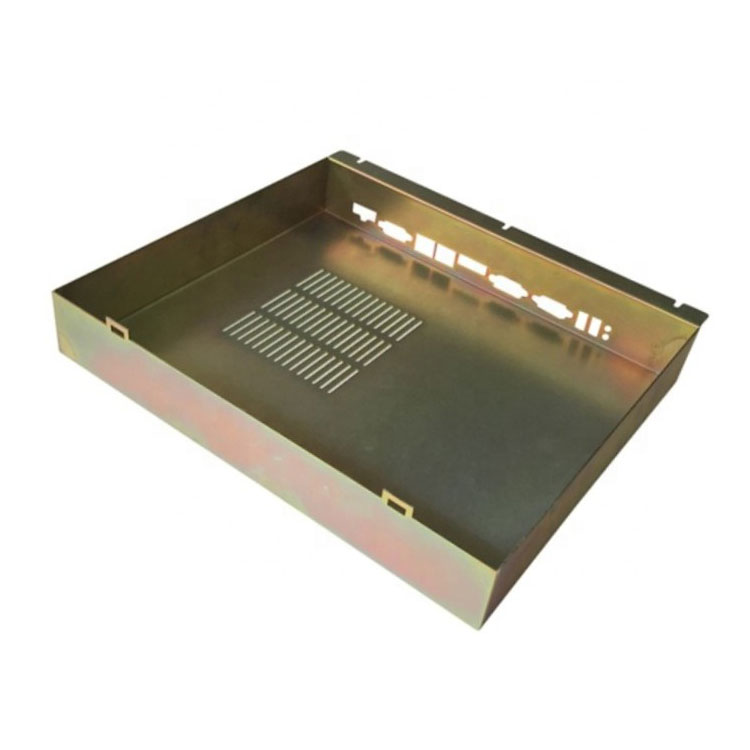

Product detail pictures:

Related Product Guide:

The pretty loaded projects management experiences and one to a person support model make the high importance of business enterprise communication and our easy understanding of your expectations for Manufacturer for Cnc Precision Machining - Custom Cnc Compound Machining Service metal Parts – LAMBERT , The product will supply to all over the world, such as: Ethiopia, Kuala Lumpur, Uganda, Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

Lambert sheet metal custom processing solutions provider.

With ten years of experience in foreign trade, we specialise in high precision sheet metal processing parts, laser cutting, sheet metal bending, metal brackets, sheet metal chassis shells, chassis power supply housings, etc. We are proficient in various surface treatments, brushing, polishing, sandblasting, spraying, plating, which can be applied to commercial designs, ports, bridges, infrastructure, buildings, hotels, various piping systems, etc. We have advanced processing equipment and a professional technical team of over 60 people to provide high quality and efficient processing services to our customers. We are able to produce sheet metal components of various shapes to meet our customers’ complete machining needs. We are constantly innovating and optimising our processes to ensure quality and delivery, and we are always “customer focused” to provide our customers with quality service and help them achieve success. We look forward to building long-term relationships with our customers in all areas!

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!