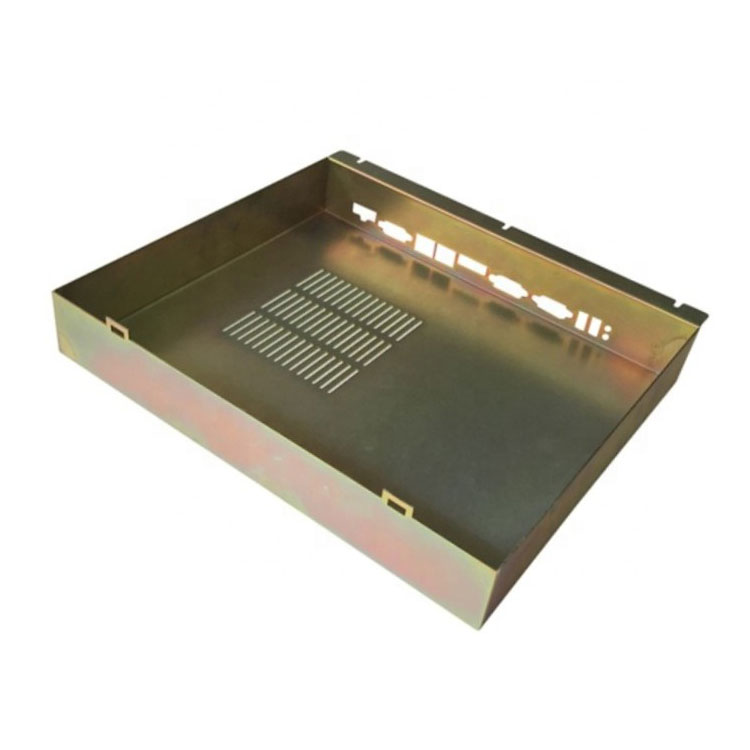

Manufacturer for Custom Sheet Metal - Custom CNC bending stamping welding metal parts – LAMBERT

Manufacturer for Custom Sheet Metal - Custom CNC bending stamping welding metal parts – LAMBERT Detail:

Detail Information

| Keywords: | sheet metal parts, metal stamping part, cnc machining metal parts, metal bending parts | Materials: | Sus, Aluminum, Iron, brass, etc. |

| Thickness: | 0.2-50mm, According To Customer Request. | Tolerance: | ± 0.05mm |

| Shape: | According To Customer’s Drawing Or Request | Size: | Customized Size |

| Application: | Industry, Agriculture, Chemical, Indoor, Outdoor, Machinery, Pharmaceutical And So On | Drawing Accepted: | All Formats(UG,ProE, Auto Cad, Solidworks, And So On) |

| Machining: | Laser Cutting, Bending,welding, Polishing,chrome, Etc. | Finish: | Chrome, Powder Coating, Black And Other Color Drawing |

| Type: | Hardware Parts,Metal Parts | Service Mode: | CNC machining service,custom metal parts service |

| Standard: | Custom High Precision Non-Standard | Surface treatment: | Powder coating,chrome,Wire drawing,etc. |

About this item

100% tested super durable quality: When choosing TZH pipe for home, TZH pipe for home is the first choice. Our durable steel parts 100% test and protect the right in the factory. Domestic TZH high quality six Angle screw joint, tightly interlocked, does not come loose after long time use. Our tube can prove desk and elegance all year round.

Our pipe parts have 10 bags, retro furniture, shelf hanging decoration of DIY project and application in your home. And I can make guan household, practice language, guan cabinetry, guan desk, industrial decoration and so on in this project. Our hexagon steel threaded pipe seam.

All pipes can be made of any shape frame and shelf for DIY furniture simply by connecting the screw rod or pipe to the hexagon steel screw pipe seam. I don’t need any screws.

Your personal DIY style is a tradition and modern decoration of simple and industrial design complement. Because of the industry’s forging steel material and simple design, it will bring one kind of loft retro charm to your home or store.

100% money back guarantee – If there is a quality problem, we will provide 90 days unconditional refund or exchange service. Contact with us at any time and we will give you a satisfactory reply. As long as our hexagonal steel screw tube joint desk, we will not let you down.

Product Description

| Application: | Used Widely |

| Machining: | laser cutting, bending, Stamping, drawing stamping |

| Material: | Stainless Steel, aluminum, alloy, iron, brass,etc. |

| Surface treatment: | Powder coating,chrome,polish,hot dip zinc |

| Quality Control: | ISO/TS9001:2015, 100% QC test before shipment. |

| Service: | Customized ODM OEM |

| Standard: | High Precision Non-standard |

| Thickness: | 0.5mm-50mm Depends |

| Tolerance: | ±0.02mm to ±0.1mm depending on the situation |

| Certificate: | ROHS, CE, CQC,ISO 9001 |

Product detail pictures:

Related Product Guide:

Sticking to the principle of "Super Quality, Satisfactory service" ,We are striving to be a good business partner of you for Manufacturer for Custom Sheet Metal - Custom CNC bending stamping welding metal parts – LAMBERT , The product will supply to all over the world, such as: Haiti, Auckland, UK, We have sufficient experience in producing products according to samples or drawings. We warmly welcome customers from home and abroad to visit our company, and to cooperate with us for a splendid future together.

Lambert sheet metal custom processing solutions provider.

With ten years of experience in foreign trade, we specialise in high precision sheet metal processing parts, laser cutting, sheet metal bending, metal brackets, sheet metal chassis shells, chassis power supply housings, etc. We are proficient in various surface treatments, brushing, polishing, sandblasting, spraying, plating, which can be applied to commercial designs, ports, bridges, infrastructure, buildings, hotels, various piping systems, etc. We have advanced processing equipment and a professional technical team of over 60 people to provide high quality and efficient processing services to our customers. We are able to produce sheet metal components of various shapes to meet our customers’ complete machining needs. We are constantly innovating and optimising our processes to ensure quality and delivery, and we are always “customer focused” to provide our customers with quality service and help them achieve success. We look forward to building long-term relationships with our customers in all areas!

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!