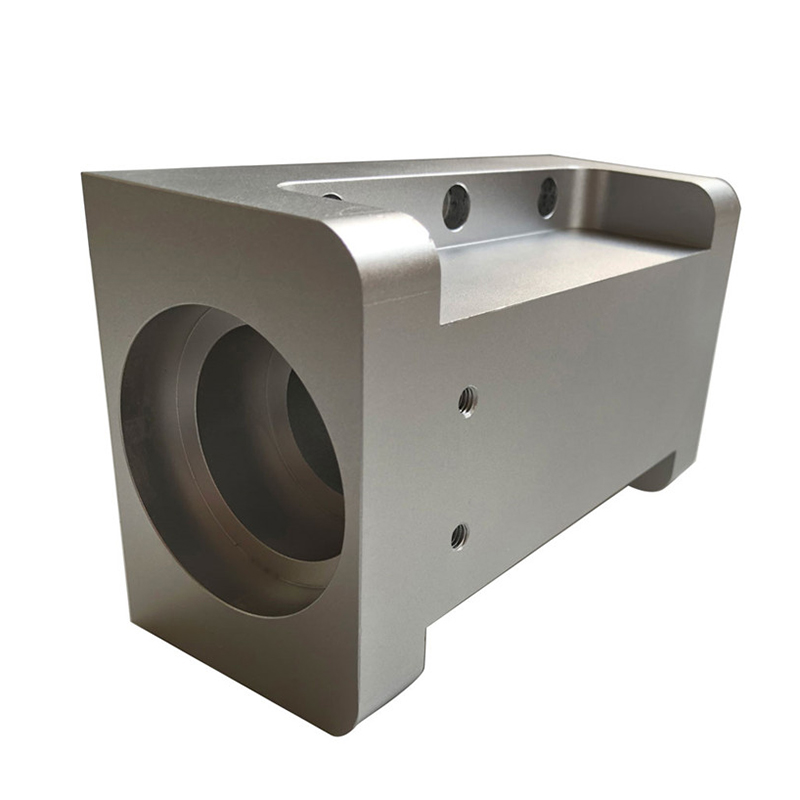

Ordinary Discount Aluminum Box Enclosure - Custom Precision Aluminum Stainless Steel Polishing service – LAMBERT

Ordinary Discount Aluminum Box Enclosure - Custom Precision Aluminum Stainless Steel Polishing service – LAMBERT Detail:

Short Description

Polishing and polishing is a finishing process that uses abrasives and work wheels or leather belts to make the surface of the workpiece smooth. Technically, polishing refers to the process of using abrasives that are glued to the working wheel, while polishing uses loose abrasives that are applied to the working wheel. Polishing is a more aggressive process, while polishing is less rough, resulting in smoother, brighter surfaces. A common misconception is that polished surfaces have mirror gloss finishes, but most mirror gloss finishes are actually polished.

Polishing is commonly used to enhance the appearance of items, prevent contamination of instruments, remove oxidation, create reflective surfaces, or prevent pipe corrosion. In metallography and metallurgy, polishing is used to produce a flat, defect-free surface so that the microstructure of a metal can be examined under a microscope. A silicon-based polishing pad or diamond solution can be used in the polishing process. Polishing stainless steel can also increase its sanitary benefits.

Use a metal polish or rust remover to remove oxidation (tarnish) from a metal object; This is also called polishing. To prevent further unnecessary oxidation, the polished metal surface may be coated with wax, oil, or paint. This is especially important for copper alloy products such as brass and bronze.

Although not as widely used as traditional mechanical polishing, electropolishing is another form of polishing that uses electrochemical principles to remove microscopic layers of metal from the base surface. This polishing method can be fine-tuned to provide finishes ranging from matte to mirror gloss. Electropolishing also has advantages over traditional manual polishing because the finished product does not undergo the compression and deformation traditionally associated with the polishing process.

Product Description

Polishing can be used to enhance and restore the appearance of certain metal parts or objects on automobiles and other vehicles, handrails, cookware, kitchenware and construction metal.

The condition of the material at hand determines which type of abrasive will be used. If the material is not finished, coarse abrasives (may be 60 or 80 grain size) are used in the first stage and finer abrasives such as 120, 180, 220/240, 320, 400 and higher grain size are used in each subsequent stage until the desired finish is achieved. Roughness (i.e., large grit) works by removing imperfections such as pits, nicks, lines and scratches from the metal surface. Finer abrasives leave lines invisible to the naked eye. No. 8 (” specular “) finish requires polishing and polishing compounds, as well as a polishing wheel attached to a high speed polishing machine or electric drill. Lubricants such as wax and kerosene although some polishing materials are specifically designed for “dry” use, they can be used as a lubricating and cooling medium during these operations. Polishing can be done manually using a stationary polishing machine or a die grinder, or it can be done automatically using special equipment.

There are two kinds of polishing actions: cutting action and color action. The cutting movement is designed to provide a uniform, smooth, semi-polished surface finish. This is achieved by moving the workpiece against the rotation of the polishing wheel, while applying moderate to hard pressure. Color movement provides a clean, bright, shiny surface finish. This is achieved by moving the workpiece with the rotation of the polishing wheel, while using moderate to light pressures.

Product detail pictures:

Related Product Guide:

Our pursuit and company goal is to "Always satisfy our customer requirements". We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for Ordinary Discount Aluminum Box Enclosure - Custom Precision Aluminum Stainless Steel Polishing service – LAMBERT , The product will supply to all over the world, such as: Irish, Indonesia, Suriname, Our organization. Situated inside the national civilized cities, the visitors is very easy, unique geographical and economic situations. We pursue a "people-oriented, meticulous manufacturing, brainstorm, construct brilliant" organization. hilosophy. Strict top quality management, fantastic service, reasonable cost in Myanmar is our stand on the premise of competition. If vital, welcome to make contact with us by our web page or telephone consultation, we are going to be pleased to serve you.

Lambert sheet metal custom processing solutions provider.

With ten years of experience in foreign trade, we specialise in high precision sheet metal processing parts, laser cutting, sheet metal bending, metal brackets, sheet metal chassis shells, chassis power supply housings, etc. We are proficient in various surface treatments, brushing, polishing, sandblasting, spraying, plating, which can be applied to commercial designs, ports, bridges, infrastructure, buildings, hotels, various piping systems, etc. We have advanced processing equipment and a professional technical team of over 60 people to provide high quality and efficient processing services to our customers. We are able to produce sheet metal components of various shapes to meet our customers’ complete machining needs. We are constantly innovating and optimising our processes to ensure quality and delivery, and we are always “customer focused” to provide our customers with quality service and help them achieve success. We look forward to building long-term relationships with our customers in all areas!

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.