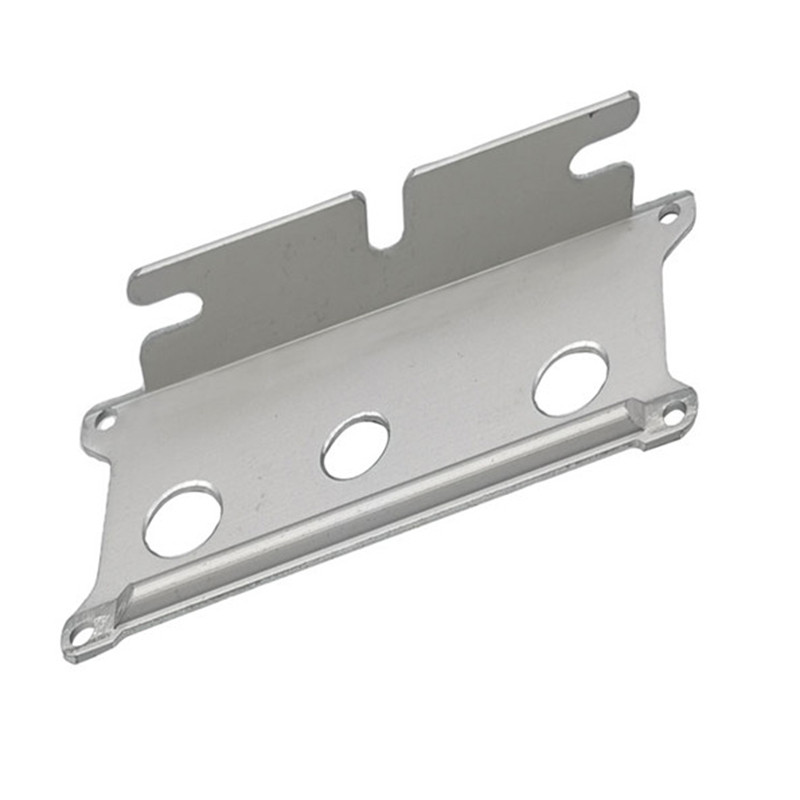

Original Factory Electrical Equipment - Custom Aluminium Iron Carbon Steel Casting / forging Service – LAMBERT

Original Factory Electrical Equipment - Custom Aluminium Iron Carbon Steel Casting / forging Service – LAMBERT Detail:

Product Description

Classification of the casting

There are many classification methods for castings: according to the different metal materials used, they are divided into steel castings, cast iron castings, copper castings, aluminum castings, magnesium castings, zinc castings, titanium castings and so on. Each type of casting can be further divided into different types according to its chemical composition or metallographic structure. For example, cast iron can be divided into gray cast iron, nodular cast iron, vermicular cast iron, malleable cast iron, alloy cast iron, etc.

According to the different casting methods, castings can be divided into ordinary sand castings, metal castings, die castings, centrifugal castings, continuous casting parts, investment castings, ceramic castings, electroslag remelting castings, bimetal castings, etc. Among them, ordinary sand casting is the most used, accounting for about 80% of the total casting output. And aluminum, magnesium, zinc and other non-ferrous metal castings, most of them are die castings.

Pouring process

In the casting process of machine bed castings, the principle of high-temperature oven and low-temperature casting should be followed. Because raising the temperature of molten metal is beneficial to the complete melting of inclusions, slag floating, easy to remove slag and degassing, reduce the slag inclusion and porosity defects of machine tool castings; The lower casting temperature is beneficial to reduce the gas solubility of liquid metal, liquid shrinkage and the baking of high temperature liquid metal on the surface of the cavity, so as to avoid defects such as porosity, sand sticking and shrinkage cavity.

Therefore, on the premise of filling the mold cavity, a lower pouring temperature should be used as far as possible. The operation of pouring liquid metal from the ladle into the mold is called pouring. Improper pouring operation will cause defects of machine tool castings such as insufficient pouring, cold insulation, porosity, shrinkage and slag inclusion, and cause personal injury.

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is exceptional, Assistance is supreme, Reputation is first", and will sincerely create and share success with all clients for Original Factory Electrical Equipment - Custom Aluminium Iron Carbon Steel Casting / forging Service – LAMBERT , The product will supply to all over the world, such as: Israel, Paraguay, Montpellier, You can always find the products you need in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We are looking forward to work with you for a win-win situation.

Lambert sheet metal custom processing solutions provider.

With ten years of experience in foreign trade, we specialise in high precision sheet metal processing parts, laser cutting, sheet metal bending, metal brackets, sheet metal chassis shells, chassis power supply housings, etc. We are proficient in various surface treatments, brushing, polishing, sandblasting, spraying, plating, which can be applied to commercial designs, ports, bridges, infrastructure, buildings, hotels, various piping systems, etc. We have advanced processing equipment and a professional technical team of over 60 people to provide high quality and efficient processing services to our customers. We are able to produce sheet metal components of various shapes to meet our customers’ complete machining needs. We are constantly innovating and optimising our processes to ensure quality and delivery, and we are always “customer focused” to provide our customers with quality service and help them achieve success. We look forward to building long-term relationships with our customers in all areas!

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!