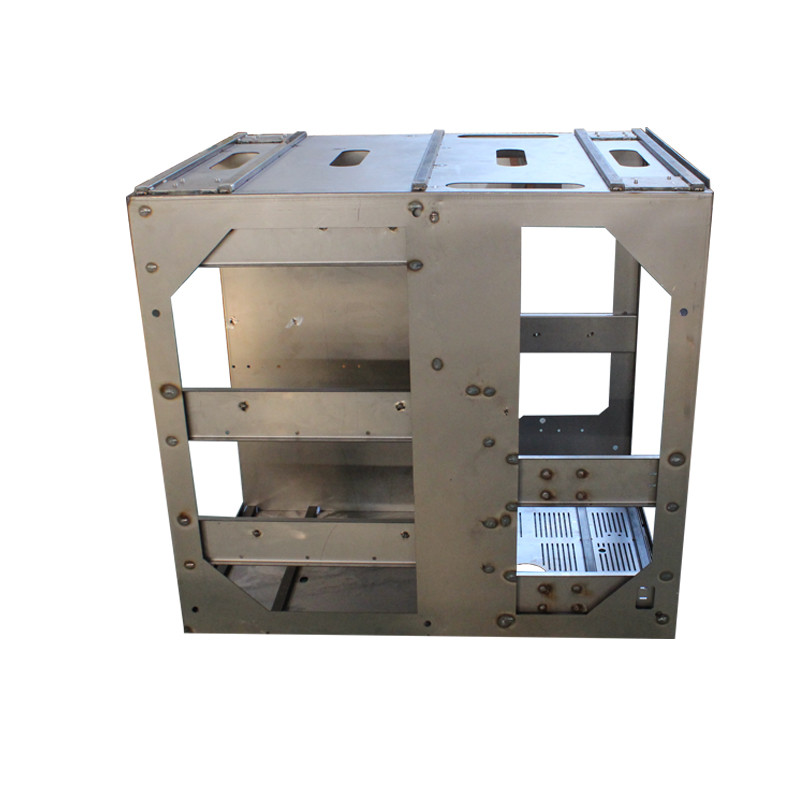

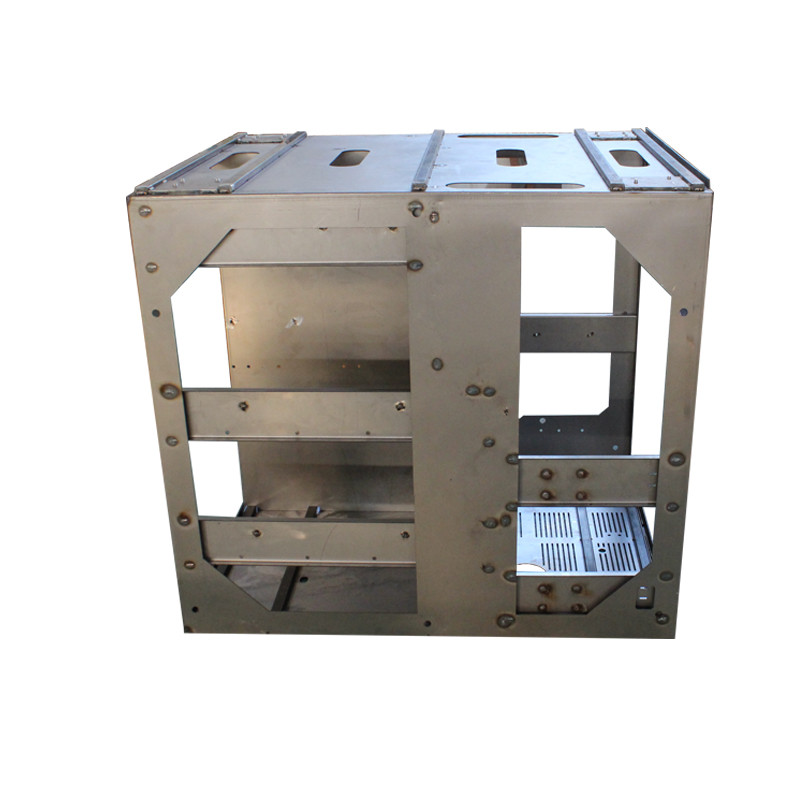

Top Suppliers Metal Table Legs - Custom Stainless Steel Metal Parts welding Service – LAMBERT

Top Suppliers Metal Table Legs - Custom Stainless Steel Metal Parts welding Service – LAMBERT Detail:

Product Description

Resistance welding

Resistance welding is a welding method in which the workpiece is combined and pressure is applied through the electrode, and the electric current is applied through the resistance heat generated by the contact surface and adjacent area of the joint. Resistance welding is a method of heating the workpiece to a molten or plastic state by the electric current flowing through the contact surface and adjacent areas. There are four main resistance welding methods, namely spot welding, seam welding, projection welding and butt welding.

Carbon dioxide welding

The shielding gas of carbon dioxide arc welding is carbon dioxide (sometimes a mixture of CO2+Ar). Mainly used for manual welding. Due to the special influence of the thermal physical properties of carbon dioxide gas, when using conventional welding power supply, it is impossible to form a balanced axial free transition by melting the metal at the welding wire end, which usually requires short circuit and droplet necking explosion. Therefore, compared with MIG welding free transition, there is more splash. But if the use of high quality welding machine, the right choice of parameters, can get a very stable welding process, so that the spatter is reduced to a minimum degree. Due to the low cost of the protective gas used, the weld is well formed when using short circuit transition, coupled with the use of wire containing deoxidizer can be obtained without internal defects of quality welding joint. Therefore, this welding method has become one of the most important welding methods for ferrous metal materials.

Argon arc welding

Argon arc welding is a welding technology using argon gas as a protective gas. Also known as argon body protection welding. It is to pass argon protective gas around the arc welding to isolate the air outside the welding area and prevent the oxidation of the welding area.

Argon arc welding technology is on the basis of the principle of common electric arc welding, using the argon gas protection for metal welding materials, through high current on the welding backing weld material melt into a liquid pool formation, cause the weld metal and weld material metallurgy combined with a kind of welding technology, in high temperature melting welding on argon constantly, make the weld material can not contact with oxygen in the air, Thus prevent the oxidation of welding material, so you can weld stainless steel, iron metal.

Laser welding

Laser welding can be realized by continuous or pulsed laser beam. The principle of laser welding can be divided into heat conduction welding and laser deep fusion welding. When the power density is less than 10-10 W/cm, it is heat conduction welding, and the welding depth and welding speed are slow. When the power density is greater than 10~10 W/cm, the metal surface is concave into “holes” under the action of heat, forming deep fusion welding, which has the characteristics of fast welding speed and large ratio of depth to width.

The principle of heat conduction laser welding is: the laser radiation heats the surface to be processed, and the surface heat diffuses internally through heat conduction. By controlling the laser parameters such as the width, energy, peak power and repetition frequency of the laser pulse, the workpiece is melted and a specific molten pool is formed

Product detail pictures:

Related Product Guide:

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future jointly with your esteemed company for Top Suppliers Metal Table Legs - Custom Stainless Steel Metal Parts welding Service – LAMBERT , The product will supply to all over the world, such as: Niger, Belgium, Hamburg, After years' creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good products quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

Lambert sheet metal custom processing solutions provider.

With ten years of experience in foreign trade, we specialise in high precision sheet metal processing parts, laser cutting, sheet metal bending, metal brackets, sheet metal chassis shells, chassis power supply housings, etc. We are proficient in various surface treatments, brushing, polishing, sandblasting, spraying, plating, which can be applied to commercial designs, ports, bridges, infrastructure, buildings, hotels, various piping systems, etc. We have advanced processing equipment and a professional technical team of over 60 people to provide high quality and efficient processing services to our customers. We are able to produce sheet metal components of various shapes to meet our customers’ complete machining needs. We are constantly innovating and optimising our processes to ensure quality and delivery, and we are always “customer focused” to provide our customers with quality service and help them achieve success. We look forward to building long-term relationships with our customers in all areas!

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!